File Supply Guide - How to supply your own artwork

You're in the right place to learn how to supply your artwork ready for printing. Here you'll learn the basics.

File Supply Essentials

We want the same thing that you want. We want your graphic files to print correctly first time and look like you meant them to. Below are the minimum file supply essentials you need to follow.

If you are designing something more complicated like a booklet or a StarMarque/Spot UV product, take a look at our detailed File Supply Guide or get in touch before starting your design.

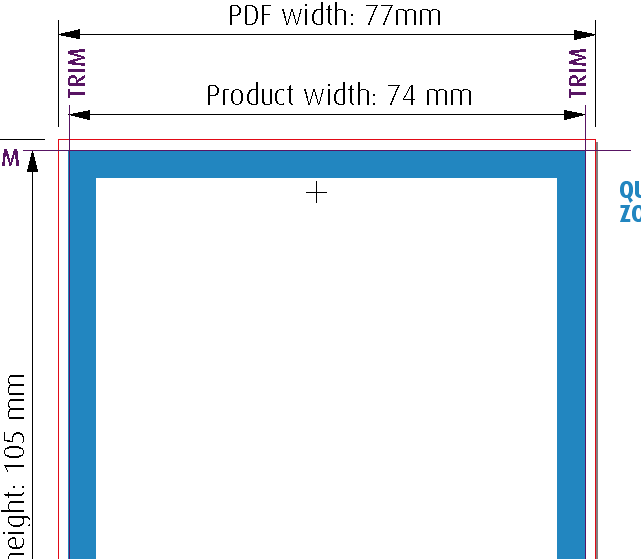

Is the Page Size and Bleed correct?

Remember to check the you have set your page size to match the product that you are ordering. Some products may have special sizes or bleed requirements. Most products generally have 1.5mm bleed on each edge, but there are some exceptions such as Booklets and Large Format Posters.

Artwork files should be supplied without crop marks.

Files supplied without a bleed will be scaled up to create the required bleed, which may result in printed elements appearing closer to the edge than expected.

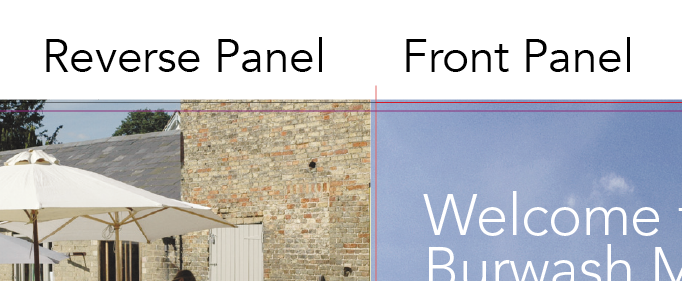

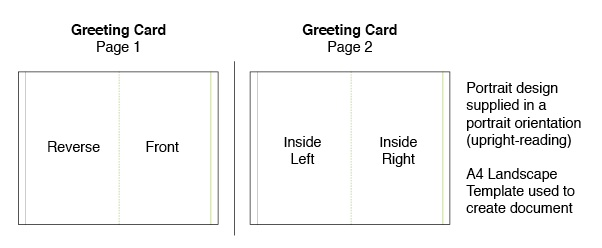

Have you checked your Artwork Orientation?

Always choose a template appropriate to the orientation of your design; it’s best to have text reading ‘upright’ on screen. If it’s not possible to design the text ‘upright’ (maybe, you need a landscape front and a portrait reverse), then you must ensure the generated artwork’s front and reverse are oriented as you need. (We impose Right to Left, place pages side by side to check the orientation of your document and view our examples here.

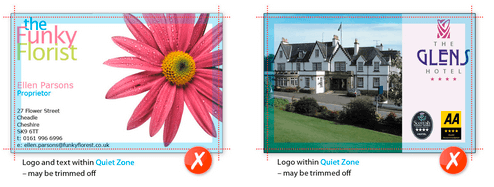

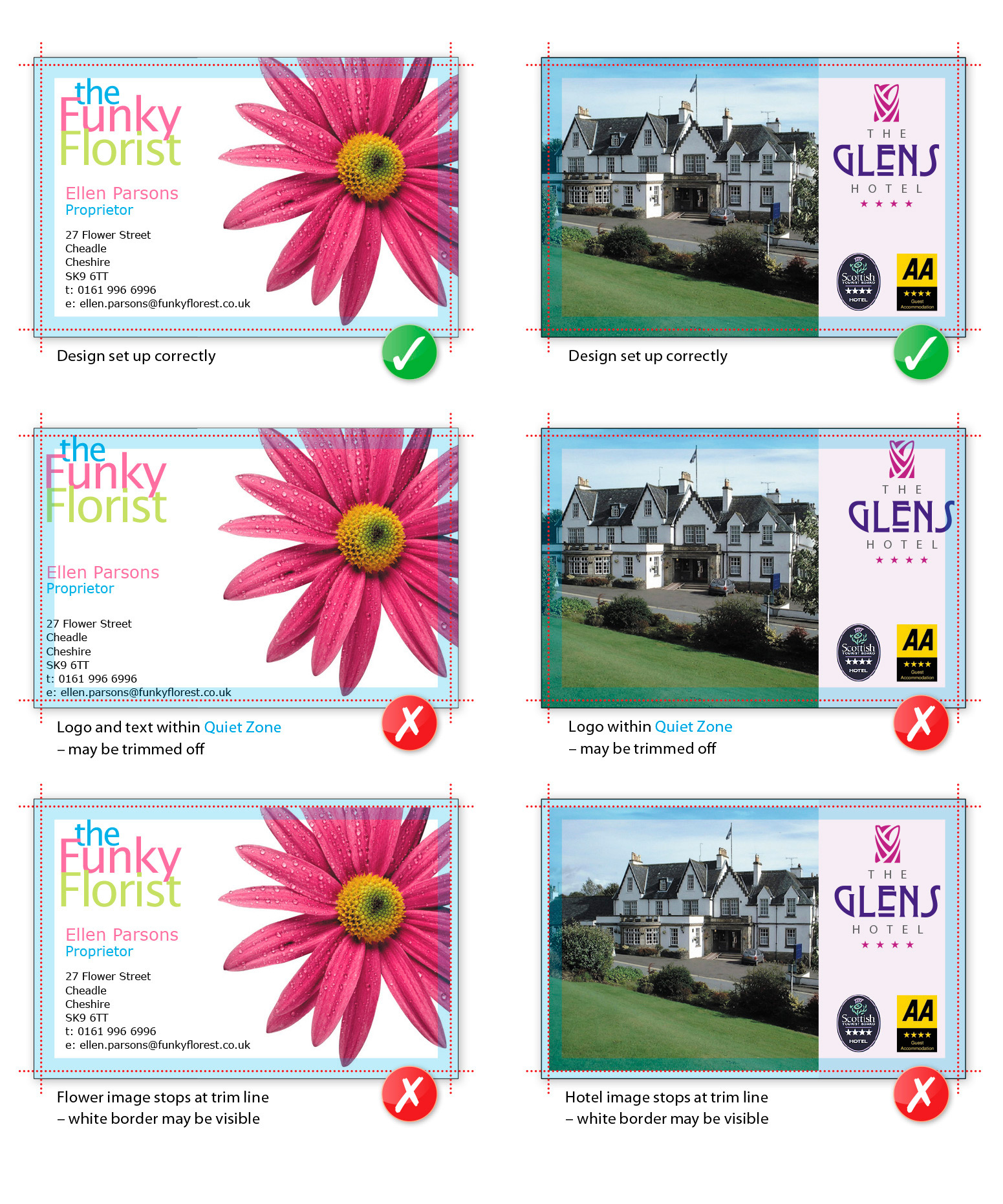

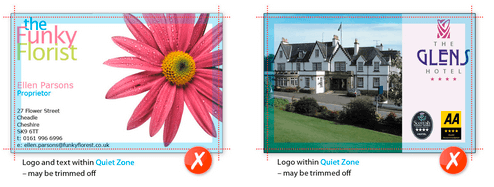

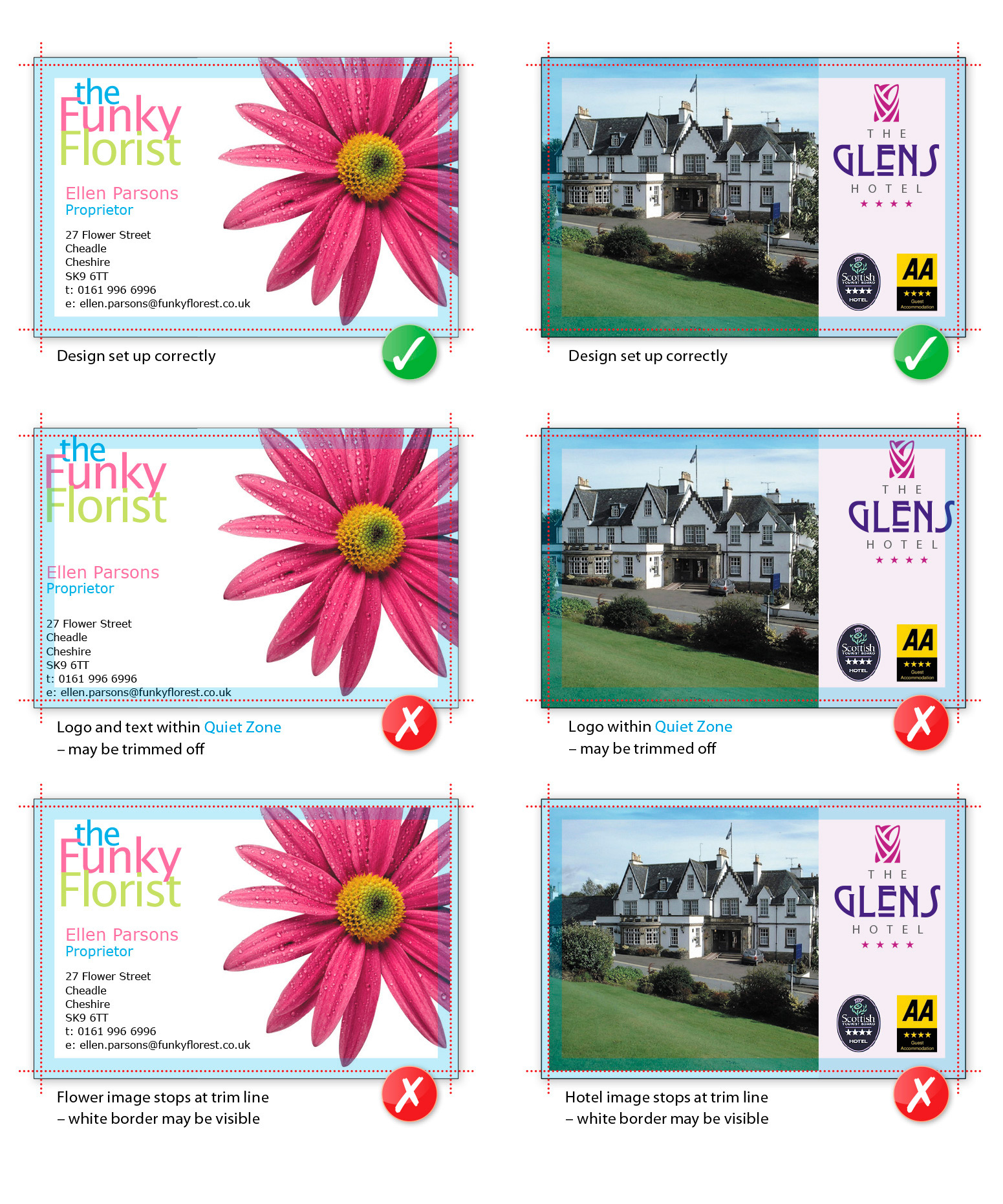

Have you observed a Quiet or safe zone?

The quiet or safe zone may vary depending on the product ordered, you’ll need to check that you don’t have any important elements in this area. For most of our products we ask that all important elements are 4mm away from the cut edge, or 5.5mm away from the page edge. Elements within this area may appear closer to the edge than expected when guillotined and often result in an uneven looking design.

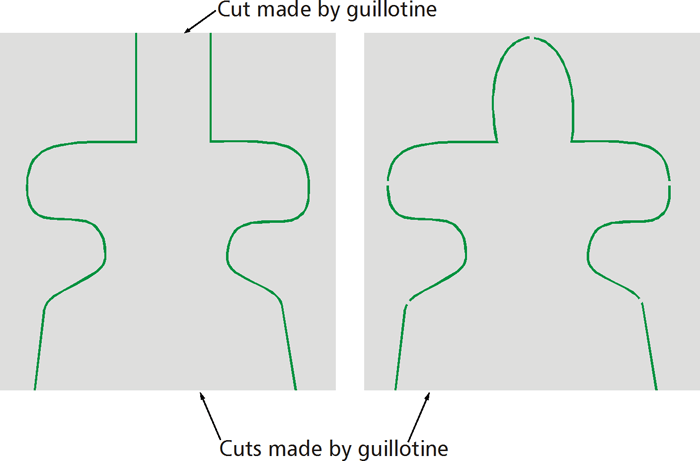

Designed margins

The use of designed margins or uniform borders near the product edge is strongly discouraged because guillotine cutting is not accurate enough to ensure that margins will be of the same width on every edge. Even a 0.5 mm movement in the guillotine blade will make the margin look uneven. Our guillotine tolerances are ± 1 mm for Litho Products and ±2 mm for Digital and Large Format.

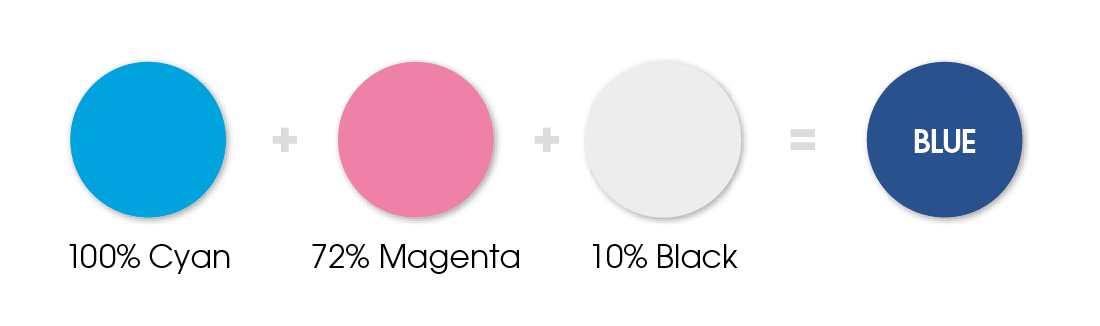

Have you used the correct colour mode?

When saving your file, ensure that you have set the artwork up in the correct colour mode for the product that you are ordering. Most products are produced in CMYK process colour. If RGB or LAB colours are found they will be converted to CMYK which will result in some colour shift. We do not recommend supplying files in RGB or LAB as it's unlikely they'll print as expected. Pantone Colours will also be converted to CMYK (where applicable) with the same results.

An example of an image supplied in RGB:

.jpg)

.jpg)

The same image once converted to CMYK:

%20600.jpg)

%20600.jpg)

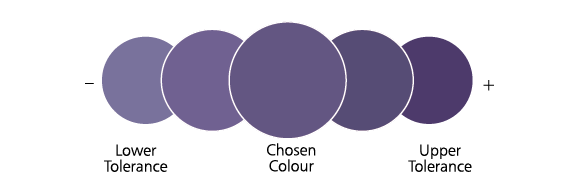

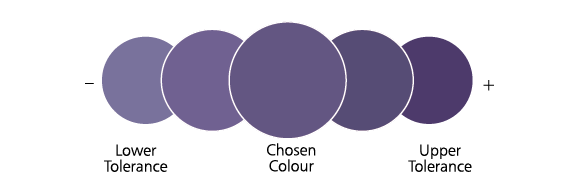

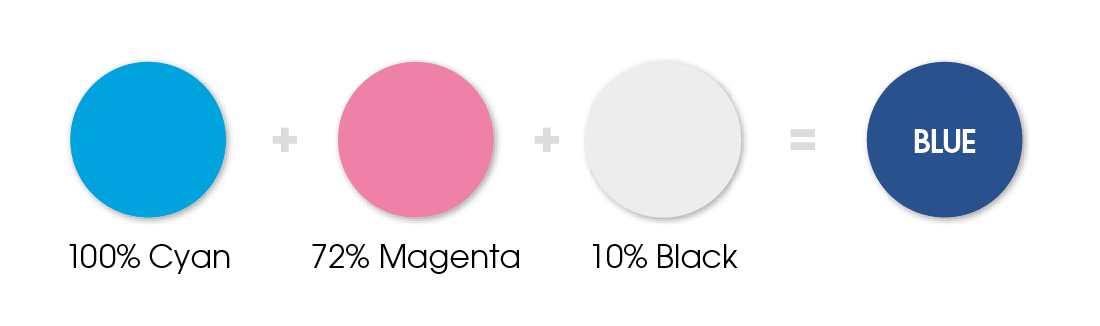

Colour Tolerances/Variation

Colour variation is inherent in any print process, unfortunately an exact colour match cannot be guaranteed and should not be expected. The example below will give you an idea of how your chosen colour may actually look when printed. It's worth bearing this in mind when placing orders for multiple sets of business cards and reorders as colour variation affects each printed job and can also vary throughout a print run; due to air temperature, humidity and many other factors outside of our control.

Colours made up of 2 or more CMYK colour channels increase the amount of variation you can expect to receive.

Example: 1 CMYK colour channel (Cyan)

Example: 3 CMYK colour channels (Magenta, Yellow & Black)

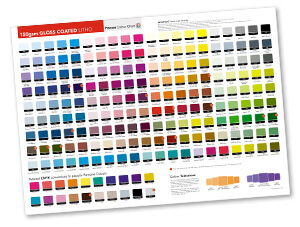

Colour charts are available for our main paper and card stocks and can be used to get a better indication of your printed colours.

Have you checked your ink levels?

Make sure all colours are below a 300% total ink coverage for coated papers and 225% for uncoated. Lower limits apply to some papers, take a look at our full guidelines for recommended ink levels.

Avoid Set-off, Misregistration and Banding

The rule of thumb:

• Avoid using more than one colour channel for Black Text (100% K only reduces the likelyhood of misregistration, which results from aligning multiple plates with fine details).

• Use a Rich Black (100% Black (K) and 40% Cyan OR 100% Black (K) and 40% Magenta) for areas over 2cm squared in size to avoid banding as single colour blacks can appear washed out when printed across large areas.

• Avoid using Colours with an ink limit of 225% for Uncoated Stocks and 300% for Coated Stocks to reduce the likelihood of set-off, which is when ink transfers from one side to the other during guillotining.

Cracking/Chipping

When paper is folded, its interlinking fibres are compressed on one side and stretched on the other. If the outer fibres lose their hold on each other, we see this as 'cracking': an opening out of the paper on the outside. This will be more visually apparent where the design includes a dark colour across the fold. If dark colours are required please upgrade to a Laminated Product which will help to reduce the appearance of cracking. This affects any product that is creased or folded such as Folded Leaflets, Creased/Shaped Flyers and Presentation Folders.

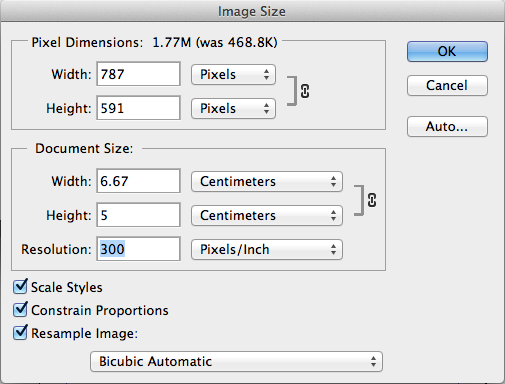

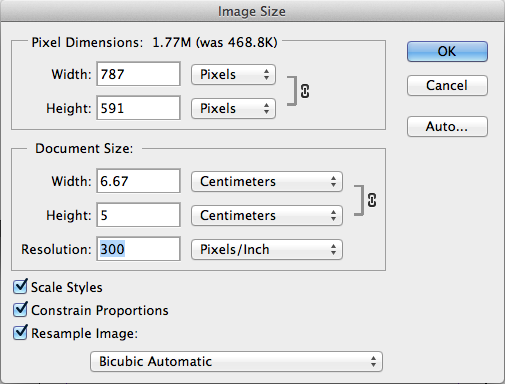

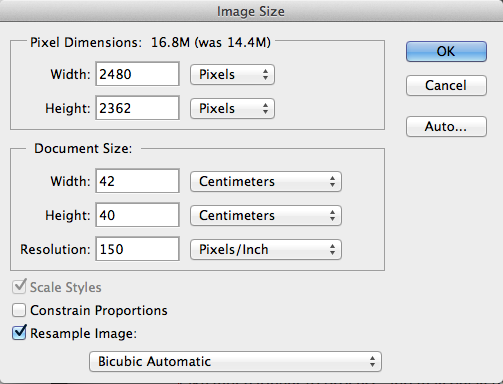

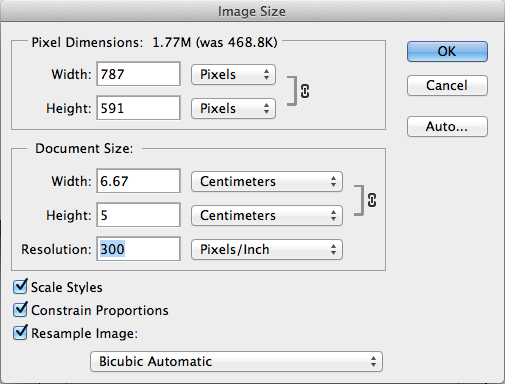

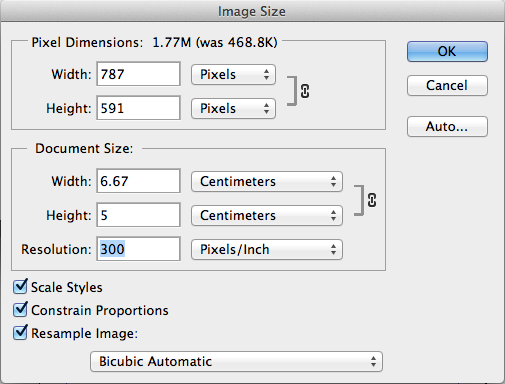

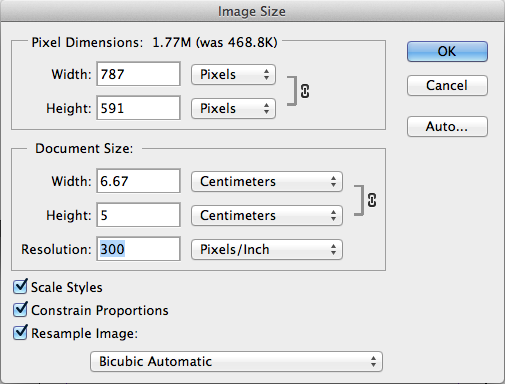

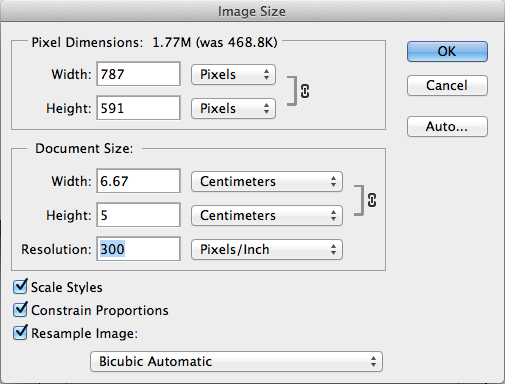

Check your image resolution?

Remember to check the requirements for the resolution of images, as it may vary for different products. For CMYK process printing, your colour images should be set to 300dpi @ 100% size.

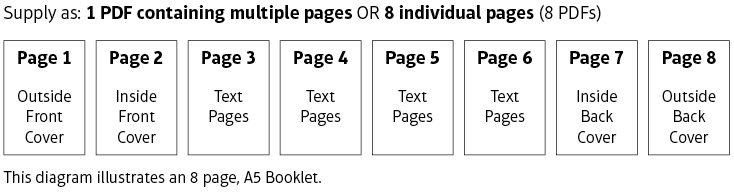

Correct number of pages?

Ensure that you supply us with the correct number of pages in your file. You can supply your pages as individual PDFs or as a multiple page PDF. Page 1 should be supplied as the front design, page 2 the reverse and finishing on page 3 where appropriate.

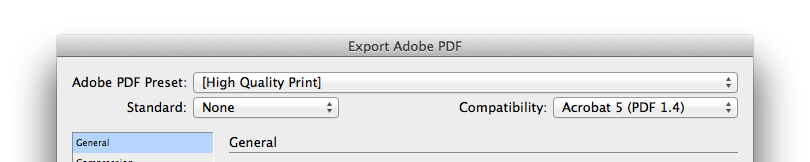

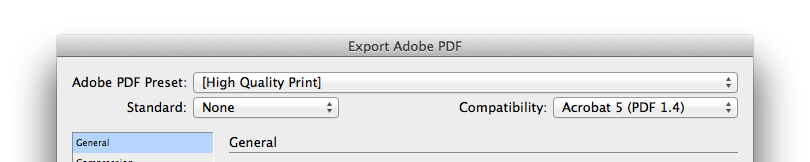

File saved in the correct format?

Remember to check that you are saving your file in the correct format for the product that you are ordering. We would prefer you to supply us with a 'Press Quality' PDF (Compatability: Acrobat 5 (PDF Version 1.4) or later). Take a look at out full list of accepted formats.

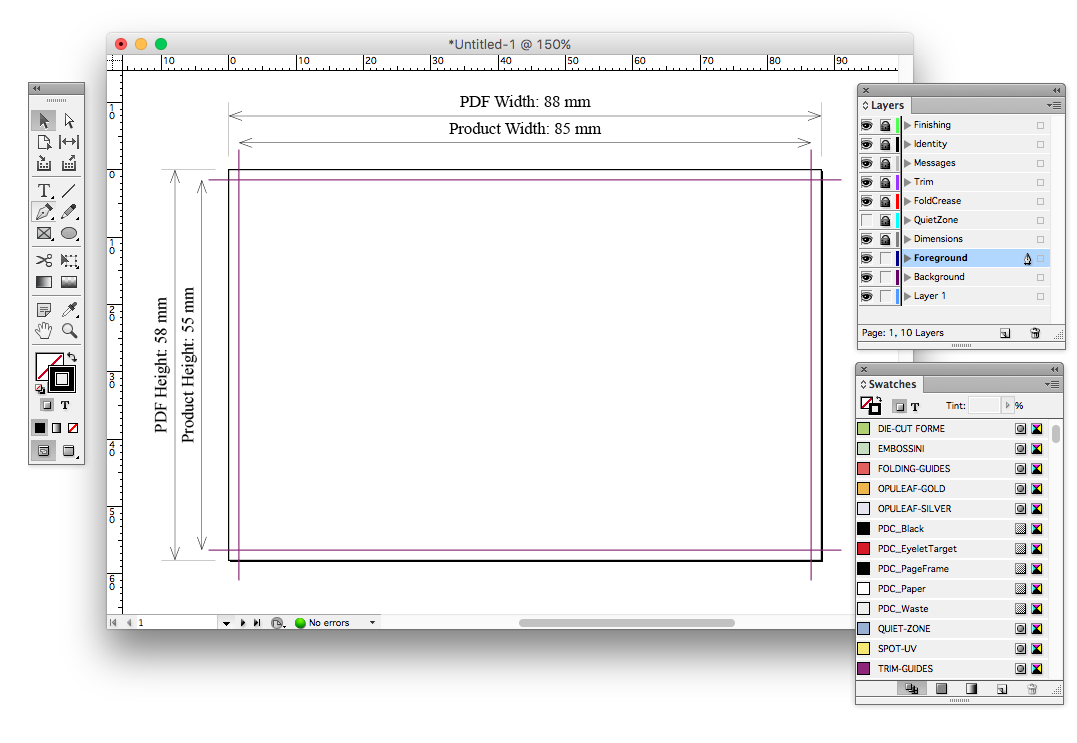

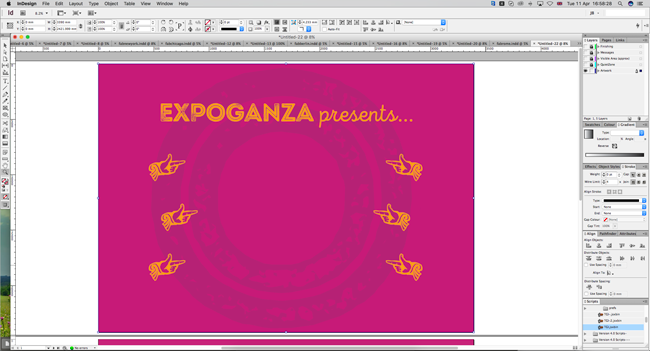

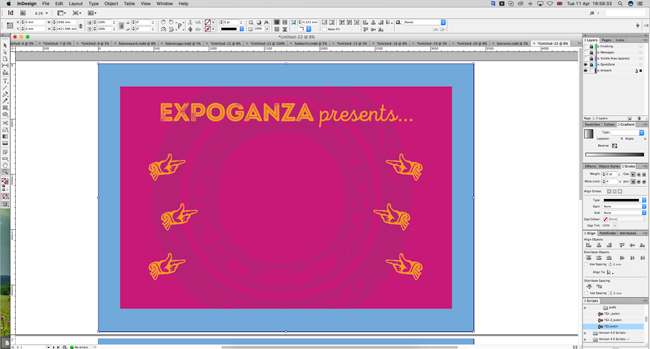

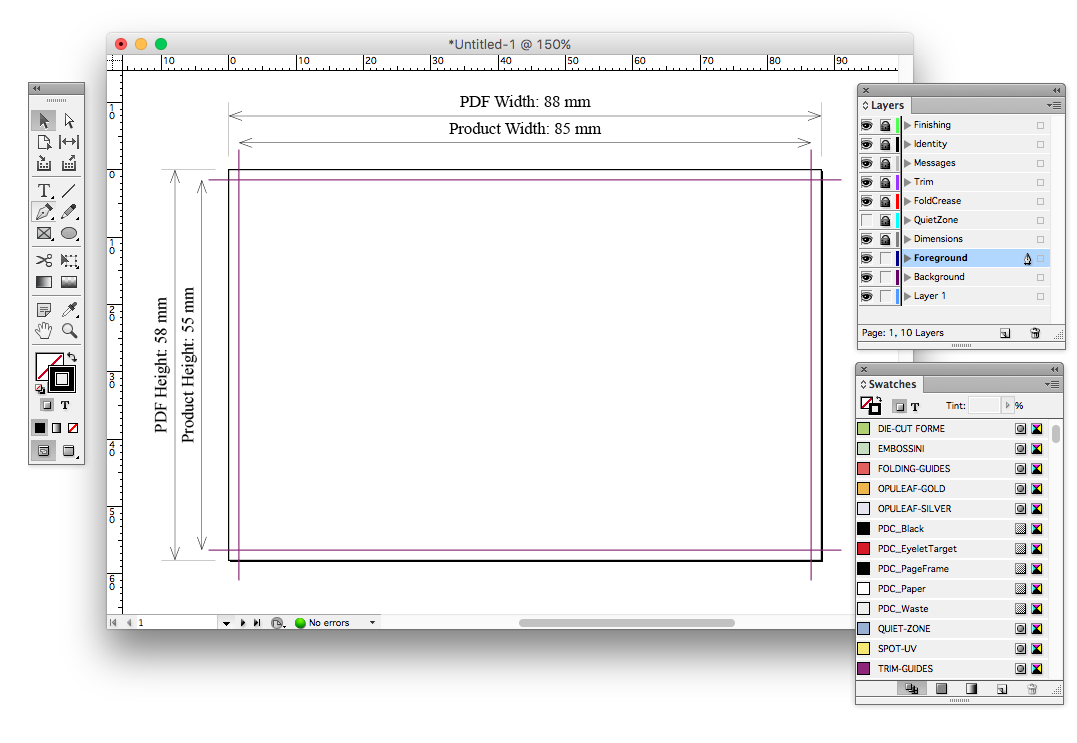

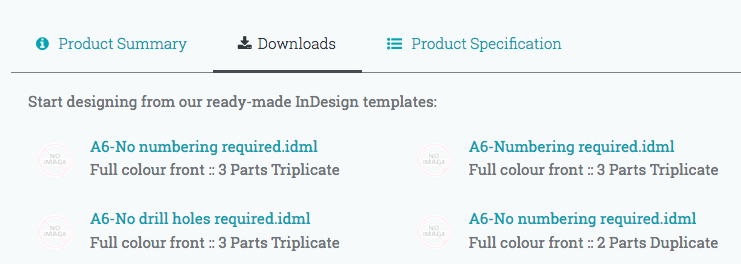

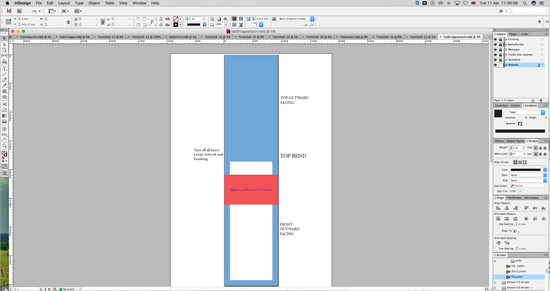

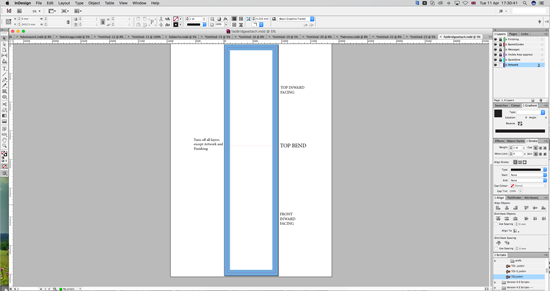

InDesign template guidance

InDesign templates are available for 99% of our product range. Templates offer an "assured" starting point for your supplied files. For Fabric products refer to Using InDesign TGI Templates for Fabric article.

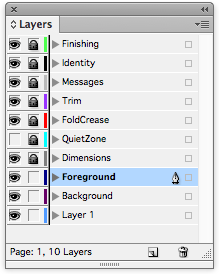

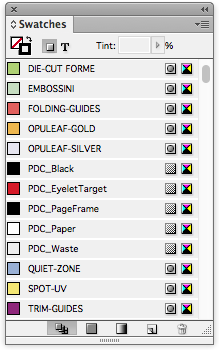

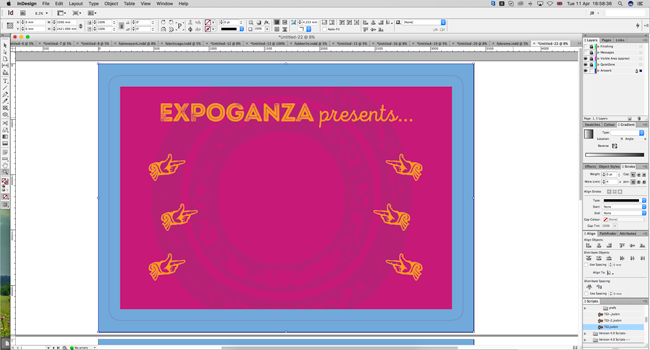

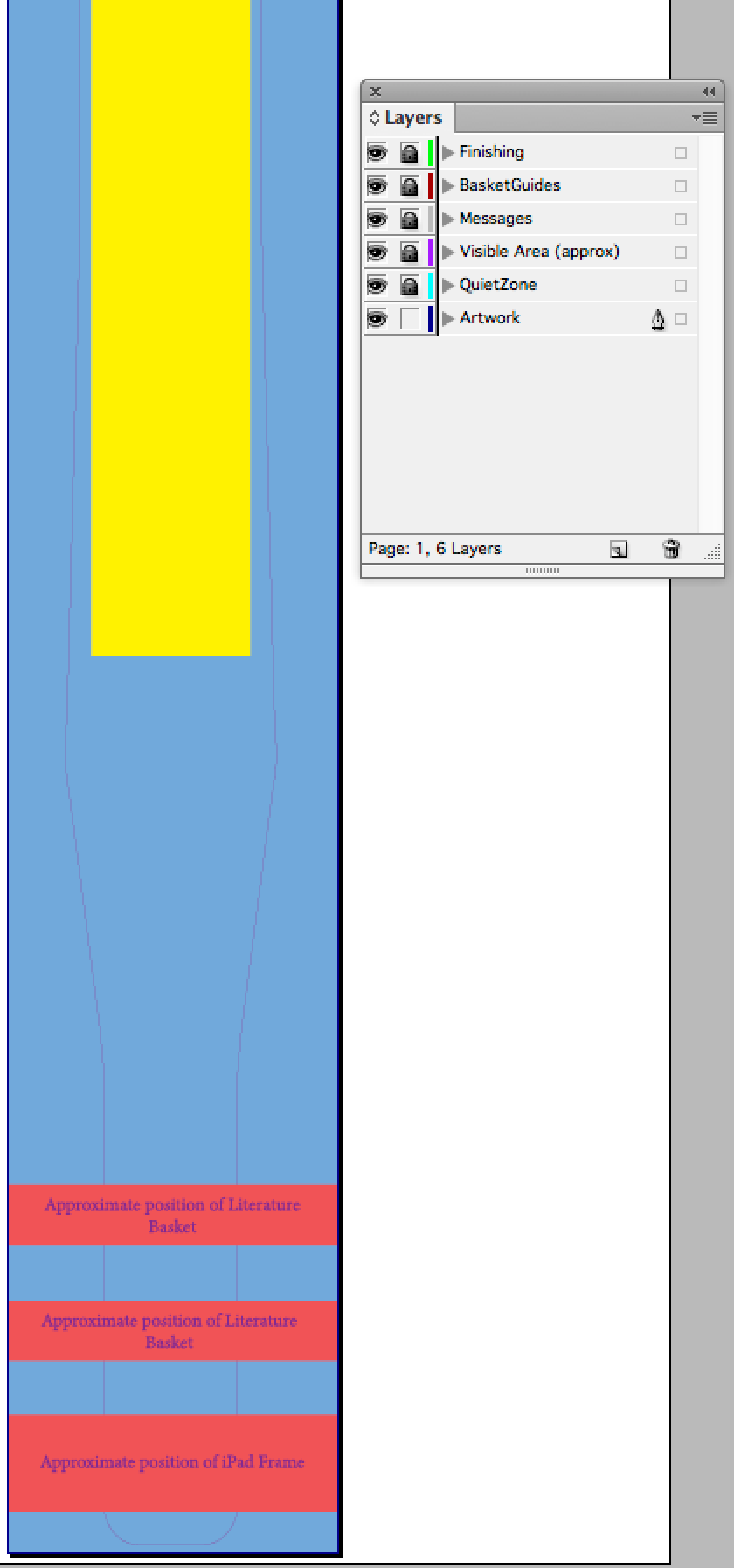

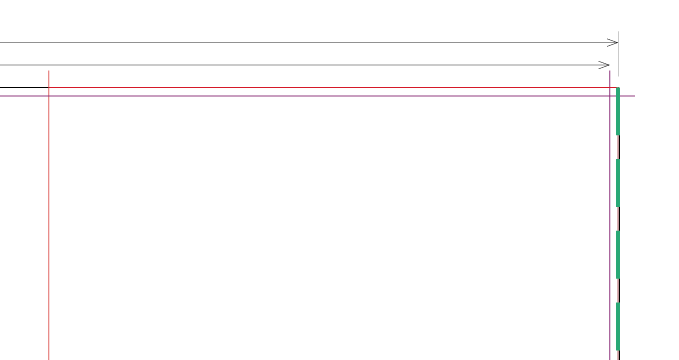

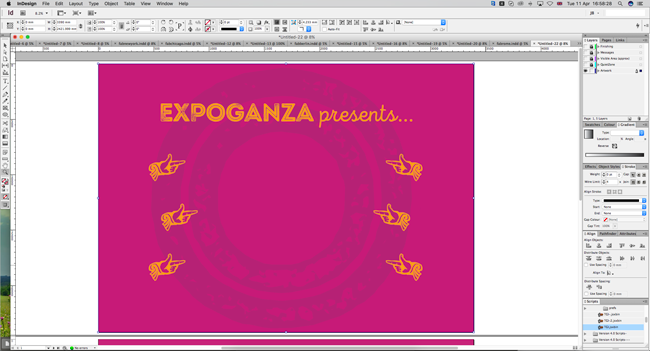

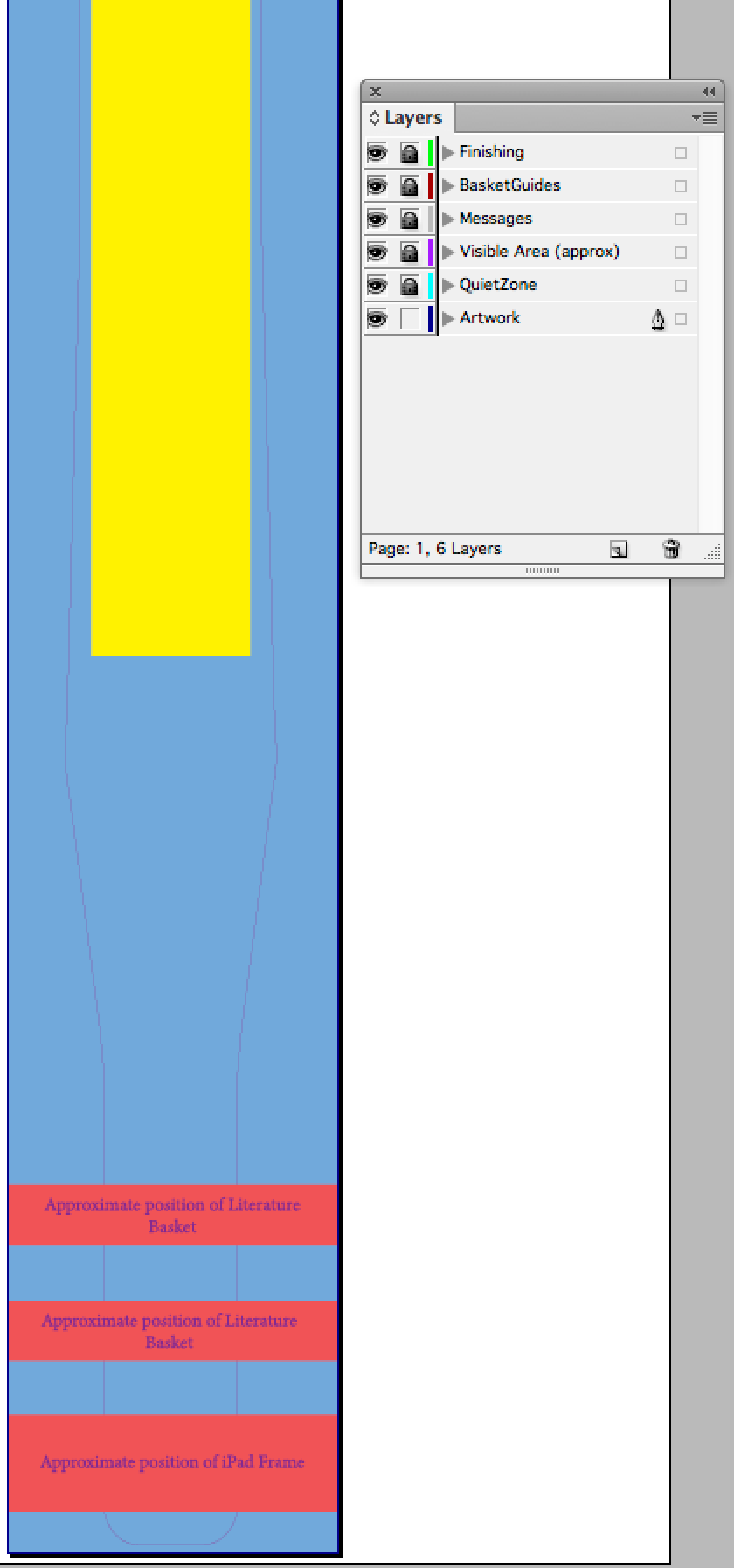

InDesign Layers

InDesign Layers

| Layer Name |

Notes |

| Foreground |

Printable layer: Your regular artwork layer, where you place your design. |

| Dimensions |

Guidance only: Shows sizes of some features such as page and trim guides |

| QuietZone |

Guidance only: Areas that you should leave clear of important elements such as text and logos. |

| FoldCrease |

Guidance only: Identifies fold and crease positions (where there are no die-cut guides) |

| Trim |

Guidance only: Shows our trim guides for guillotining |

| Messages |

Guidance only: Hints about the product or spec. |

| Identity |

Guidance only: Product code, template generation date and update version number. |

| Finishing |

Printable layer: Finishing elements that must be topmost on the artwork and are required for printing die-cuts, spot uv and folders (Folder Style ID box for example). |

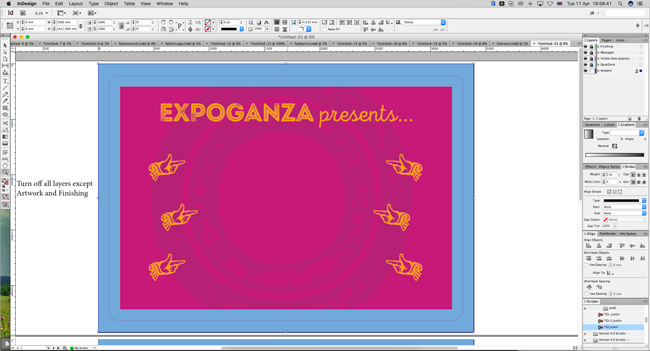

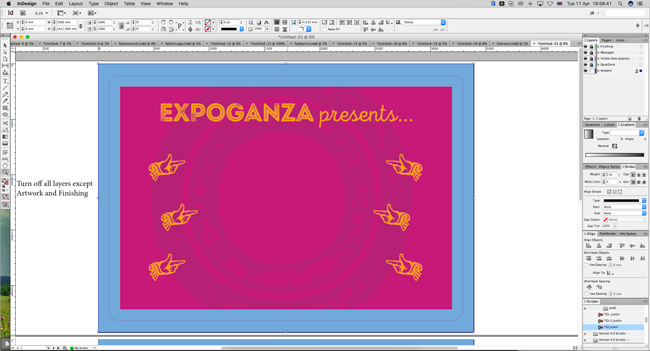

Guidance Layers

These Visual Aids are not required for printing and are removed by FileCheck (status 021). They should not appear on your "Print Ready PDF".

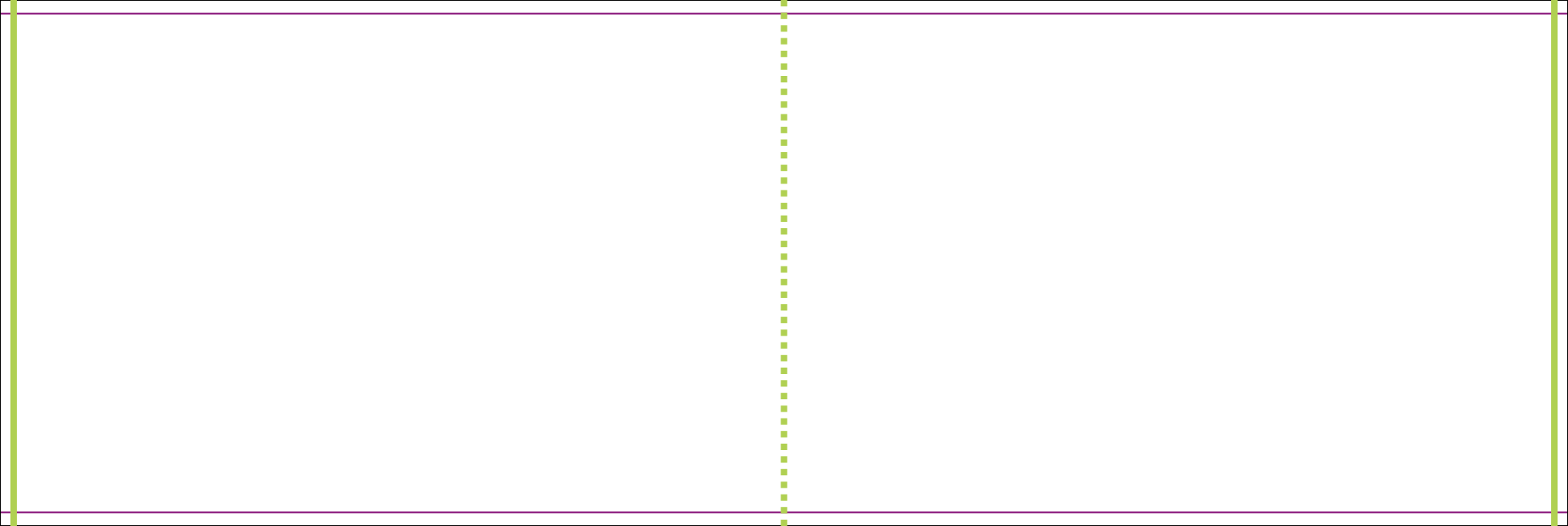

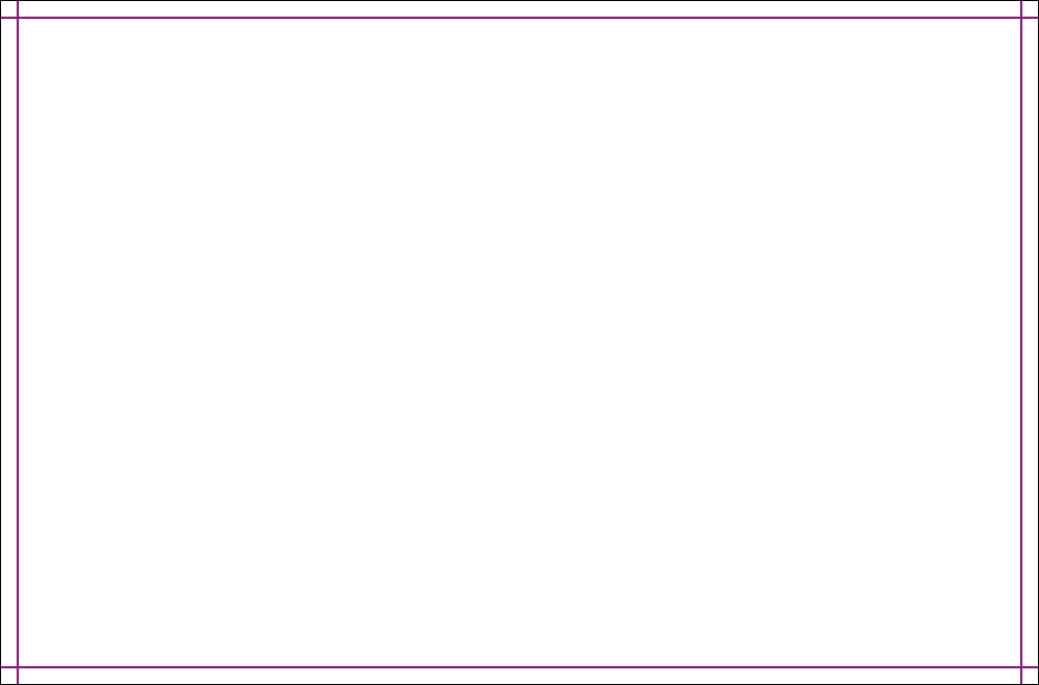

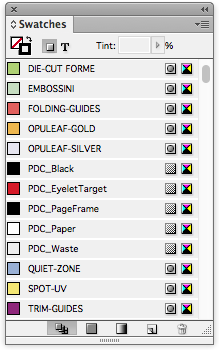

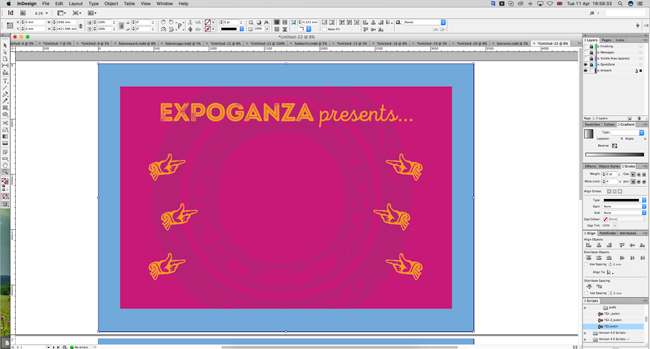

Quiet Zones

It's best practice to leave a 3 to 5mm margin (Quiet Zone) between your text and logos and the trimmed edge for Litho printed jobs.

Booklets, Banners and Fabric products have much larger Quiet Zones.

The Quiet Zone is marked in the blue QUIET-ZONE colour, on the QuietZone layer. This layer is hidden by default, and can be revealed by clicking on the ‘eye box’ (leftmost column) next to the QuietZone layer in the Layers palette.

The Quiet Zone Guide should not appear on the "Print Ready PDF" and is removed by our FileCheck Software.

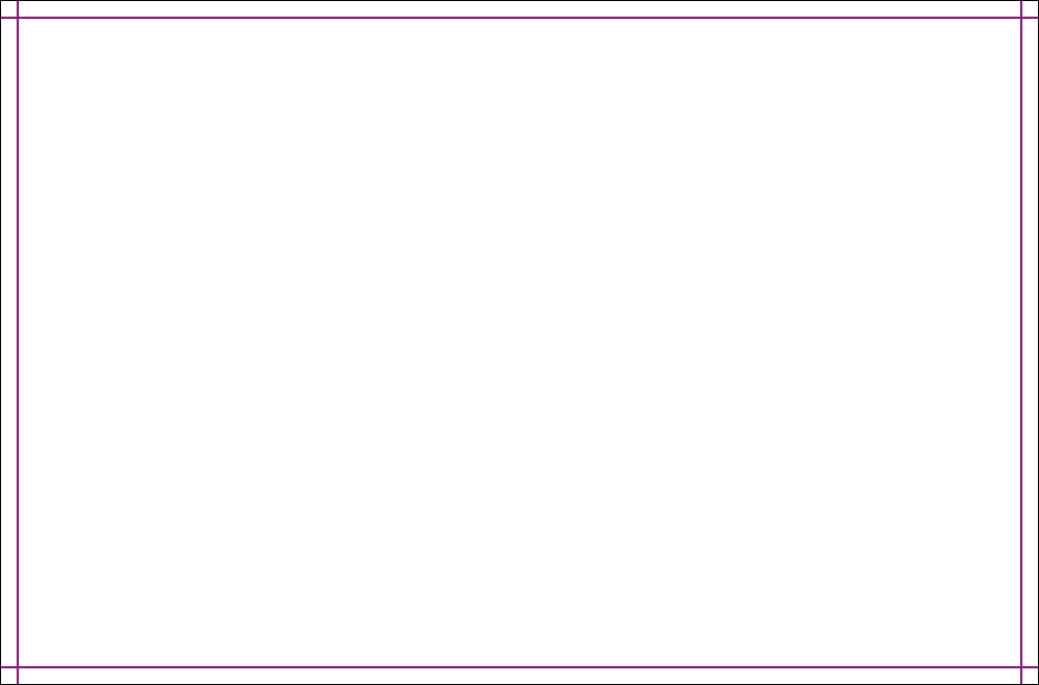

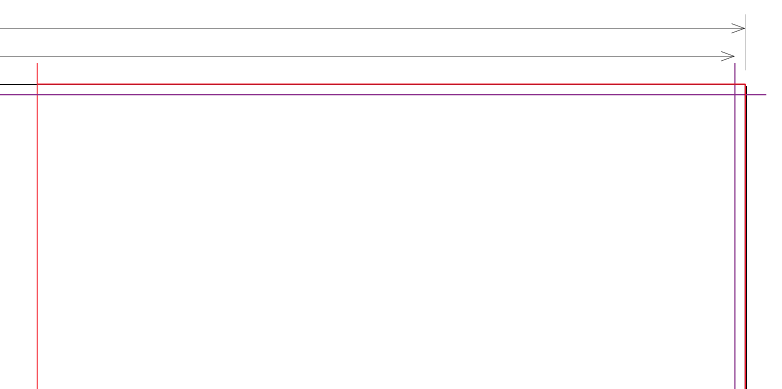

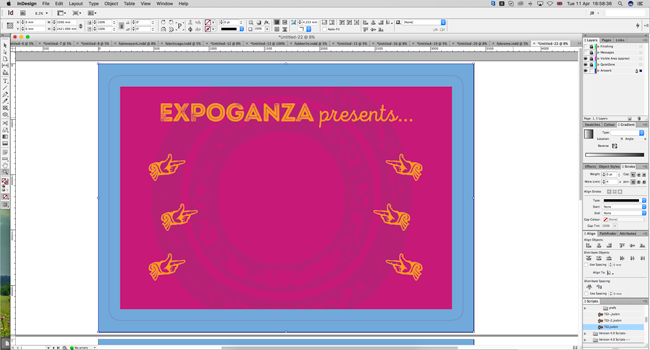

Trim Guides

These are marked in our purple TRIM-GUIDES colour, on the Trim layer, showing where the product will be trimmed. The tolerances for guillotining are -/+1mm. These elements should not appear on the PDF you send to print.

The Trim Guide should not appear on the "Print Ready PDF" and is removed by our FileCheck Software.

Fold Guides

These are marked in the FOLDING-GUIDES colour, on the Fold layer, showing where the product will folded. The tolerances for folding are -/+1mm. These elements should not appear on the PDF you send to print.

The Folding Guide should not appear on the "Print Ready PDF" and is removed by our FileCheck Software.

-1.jpg)

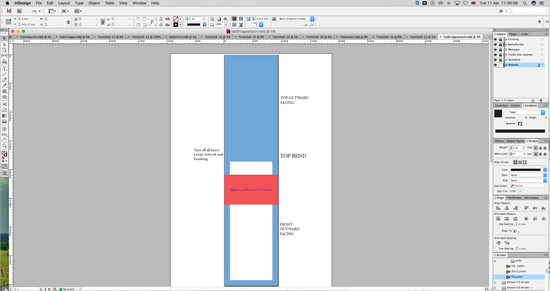

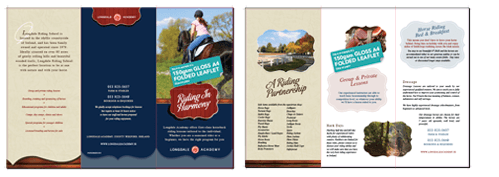

Mini Brochures and folded products

Red page frame for front panel

A red page frame is drawn to indicate the front panel on the finished item.

The Red Page Frame Guide should be present on your "Print Ready PDF".

Perforation

Where a simple perforation option is specified on leaflet products, the parallel edge closest to the perforation is marked with a dashed green+white line.

The Perforation Guide should be present on your "Print Ready PDF".

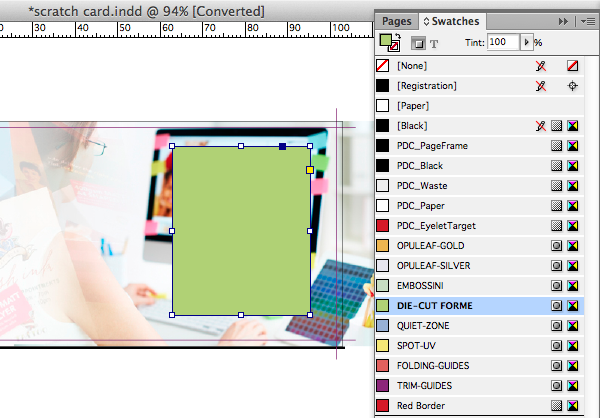

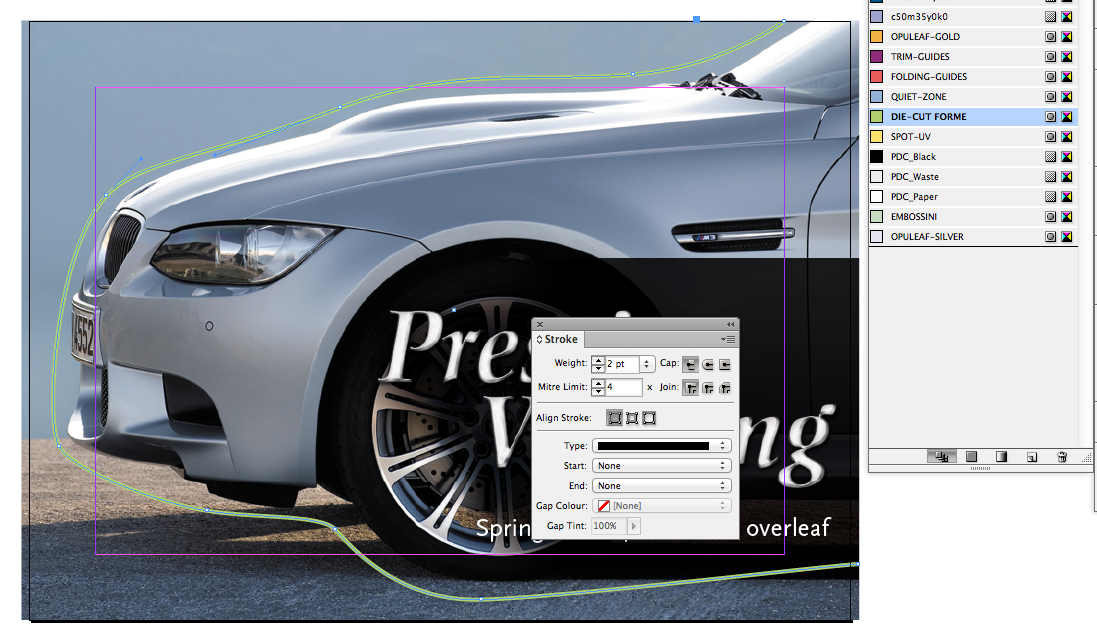

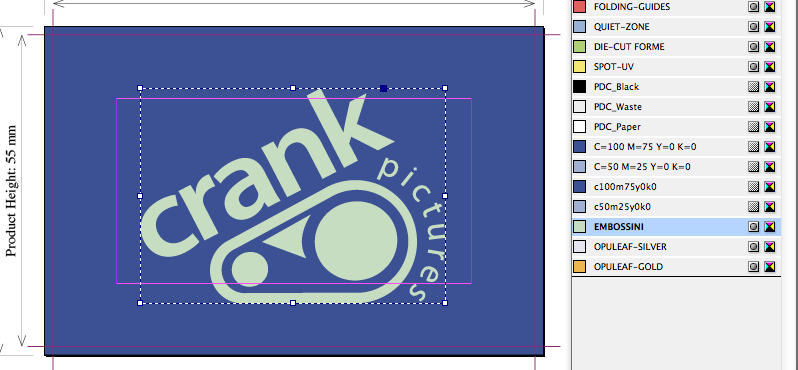

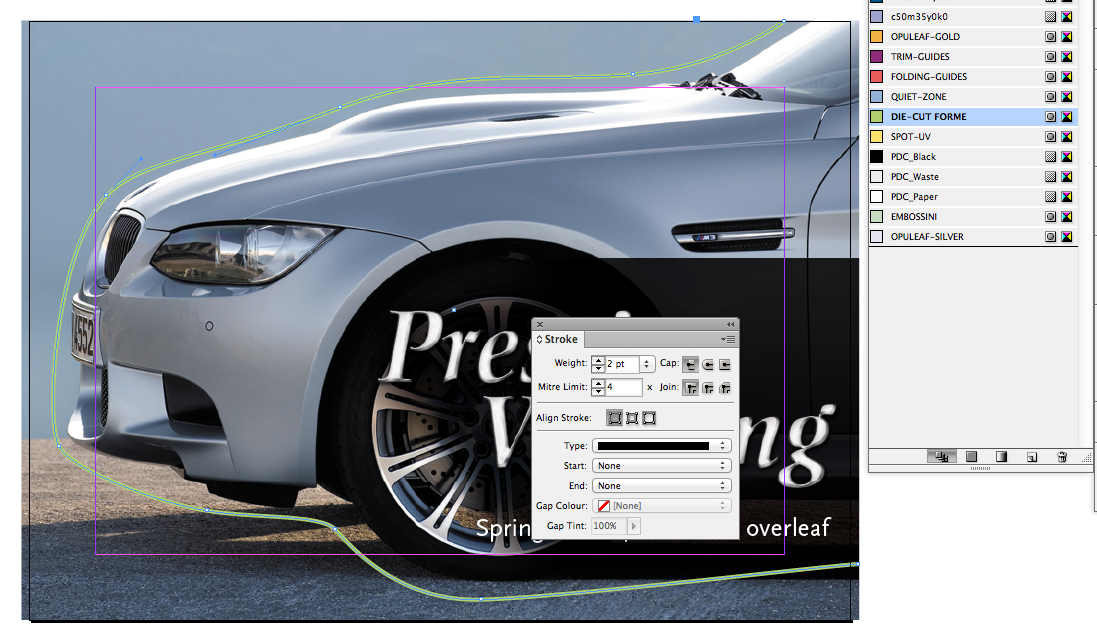

Die-cut, creased, embossed, and spot-UV products

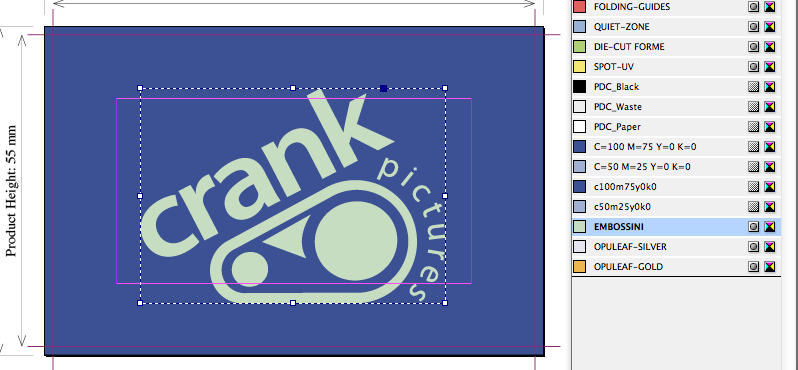

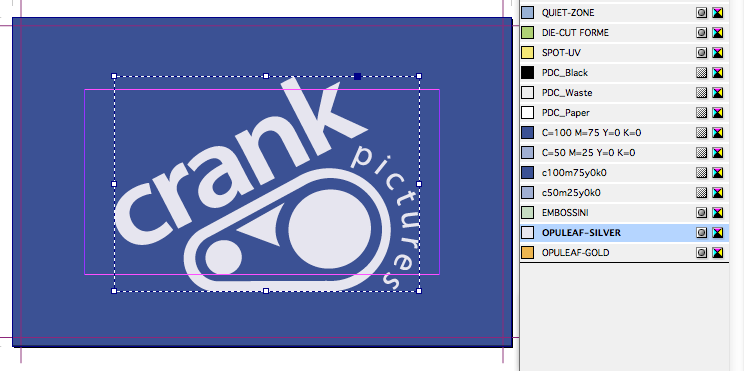

All of our templates include our die-cut, spot uv, gold or silver foil spot colours.

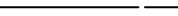

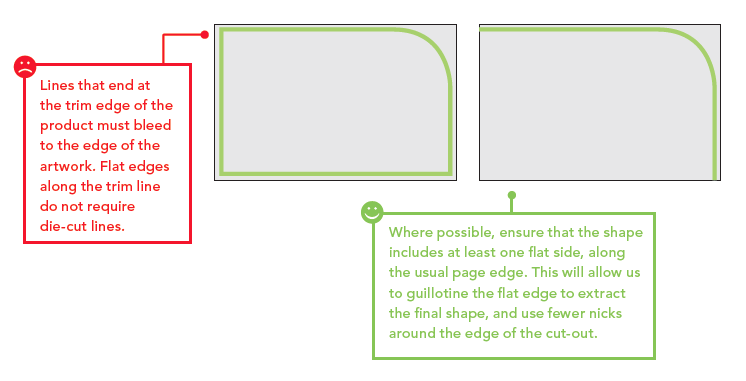

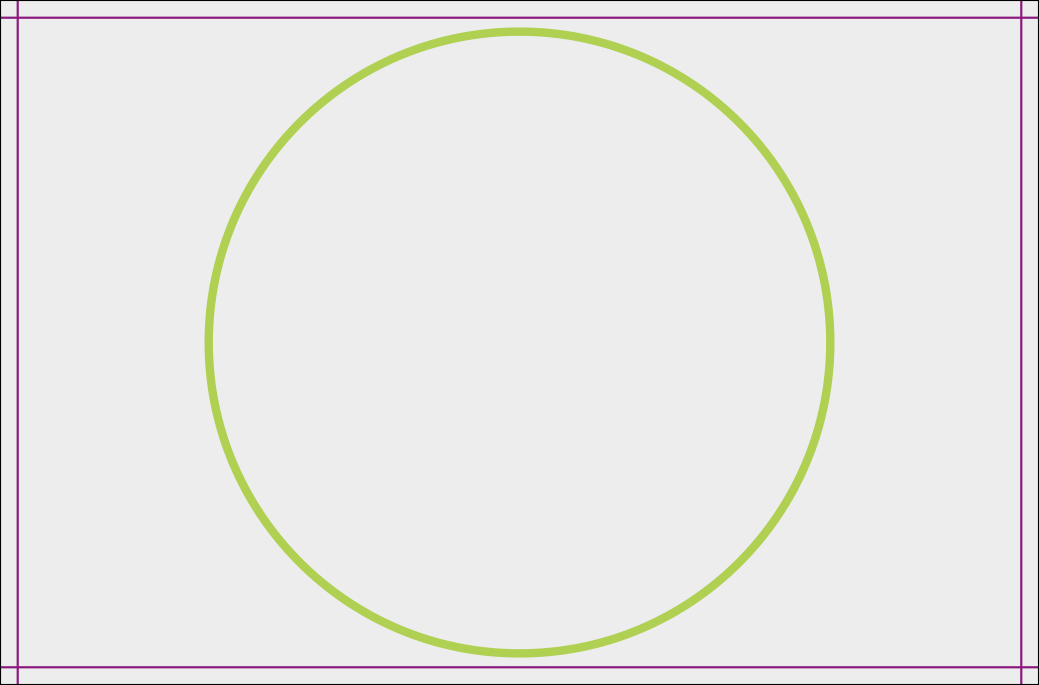

Die-cuts

Add 2pt Strokes to the Finishing layer, using swatch colour: DIE-CUT FORME.

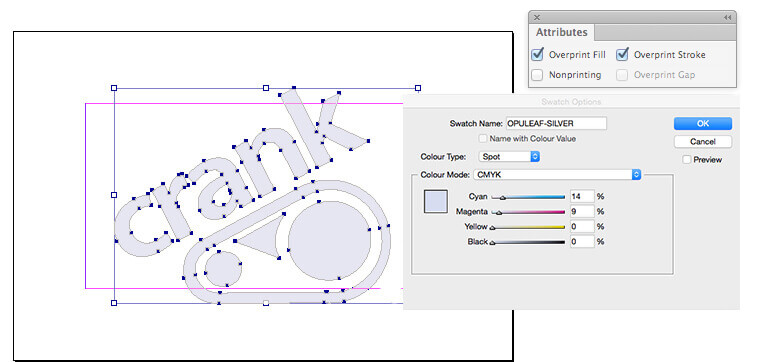

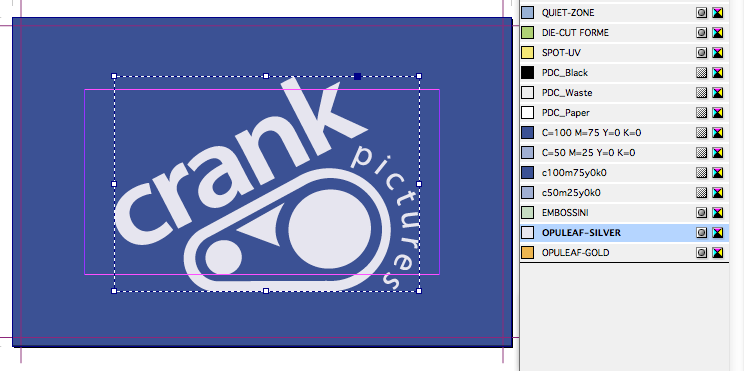

Foil

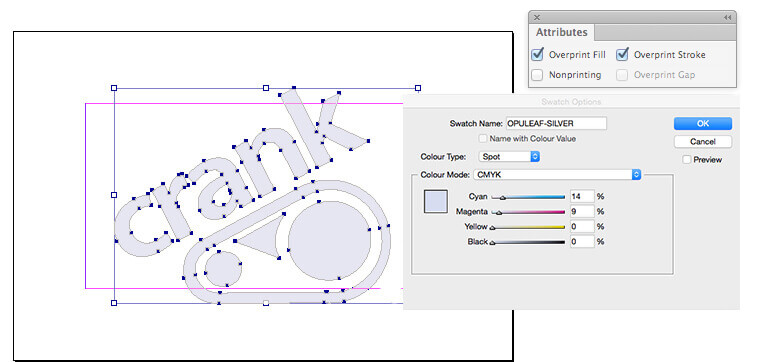

Add solid shapes to the Finishing layer, using swatch colours: OPULEAF-GOLD or OPULEAF-SILVER.

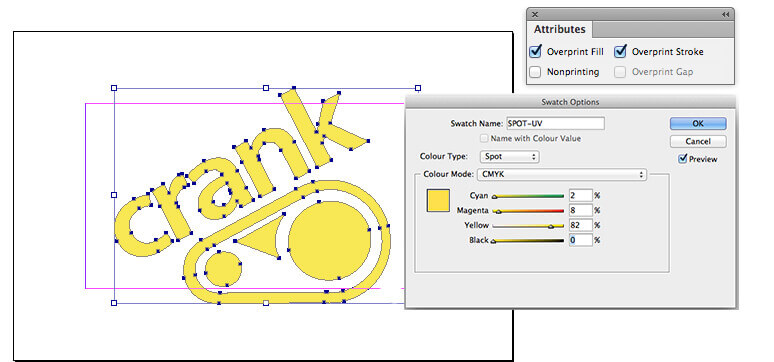

Spot-UV

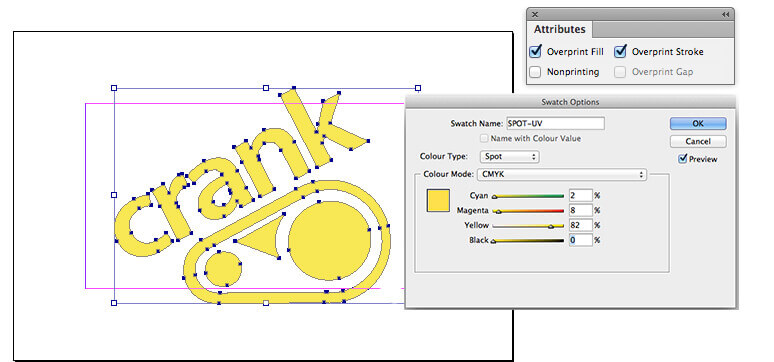

Add solid shapes to the Finishing layer, using swatch colour: SPOT-UV.

Embossing

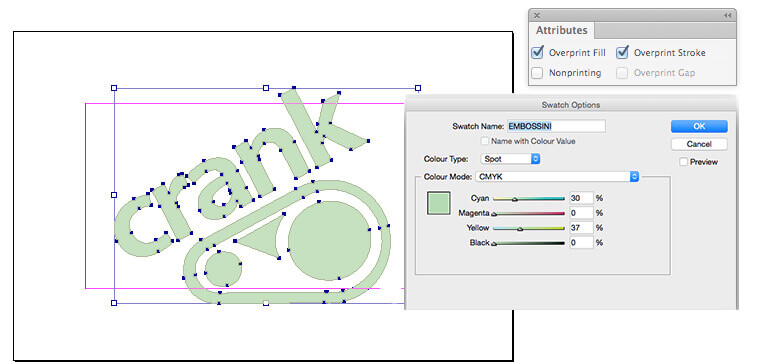

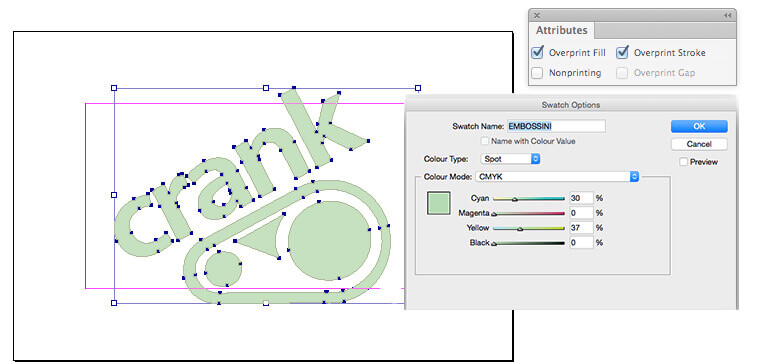

Add solid shapes to the Finishing layer, using swatch colour: EMBOSSINI.

Large Format only

- 2 pt Page Frame on the Finishing layer

- 10 mm Quiet Zone.

Eyelets

For Banners having eyelets, TGI will place eyelets with the correct spacing. This also works with custom-sized Banners.

Overview

We want your files to print perfectly.

We want your graphic files to print without fuss and look exactly like you meant them to. We’ll be honest with you – of the small number of jobs that don’t print as expected, the overwhelming majority are from files supplied to us. Even if you’re a seasoned professional and are used to supplying files for print, please read these guidelines anyway – our process is likely to be different to what you’re used to. If you’re designing something complicated, please call us before you start or look at our ‘How To’ guides.

What happens when we receive your file?

Upon receipt of your PDF, we’ll perform an automated FileCheck of your file to ensure that it meets our production requirements. Our FileCheck is industry leading, and will correct many common issues ready for print.

Post FileCheck we will:

- If no errors are found in your PDF then we will proceed to print without sending you a proof.

- If errors have been found and corrected that change the visual look of your graphic file then we’ll send you a proof with a list of what has been corrected.

- If your PDF fails our preflight then we will request a new file. If you can’t correct the issue and would like us to then we’ll send you a fixed price cost to do this.

Sometimes we can’t correct a file, such as a low resolution image, and in this case we’ll contact you to confirm how to proceed. If we have to make manual corrections to your PDF, a small fee may be incurred.

I don’t have a PDF, can you work from my native file?

Yes, absolutely. We prefer PDF files, but if you don’t have one then we’ll be able to work with your native files. Please call us to discuss your project further.

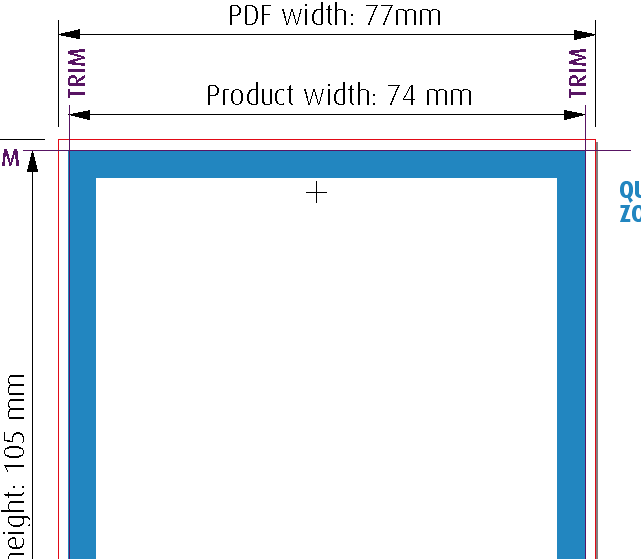

Setting your page size

It’s very important that you set your page size correctly. If you don’t,

parts of your design may be chopped off, look off-centre, or have

areas of undesired white space. Here’s what to do:

How to set page size

-

Locate the product size you’re interested on the Common Sizes page.

-

Make a note of the Page Size. This is the size you should set your page on your document.

-

Now look at the Trim Size. You’ll see that this is 3 mm smaller on both dimensions. This difference is known as the ‘bleed’ – 1.5 mm on all four sides – that’s approximately where our automated guillotines will make their cuts. The bleed allows for any small variations in during the cutting process. We recommend that if possible no objects extend beyond the page size – use the ‘paste inside’, ‘clip’, or ‘crop’ tool.

-

To remind yourself where the cuts will be made, you could add some guidelines 1.5 mm in from each edge on your document.

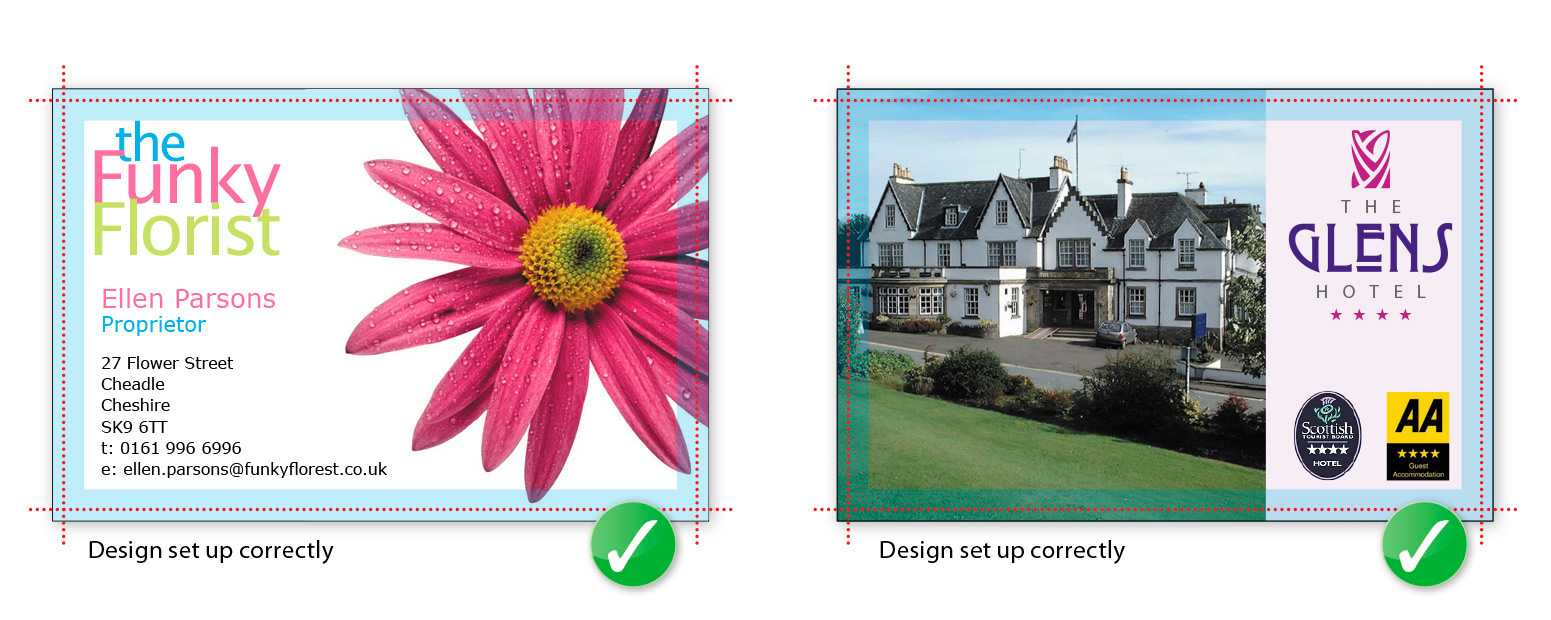

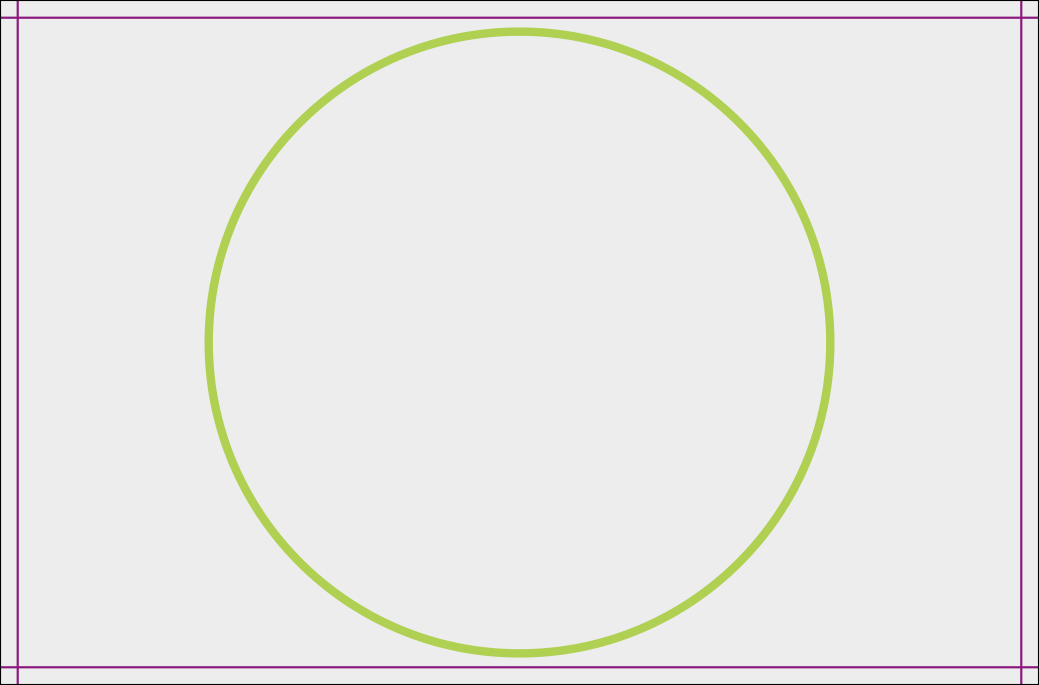

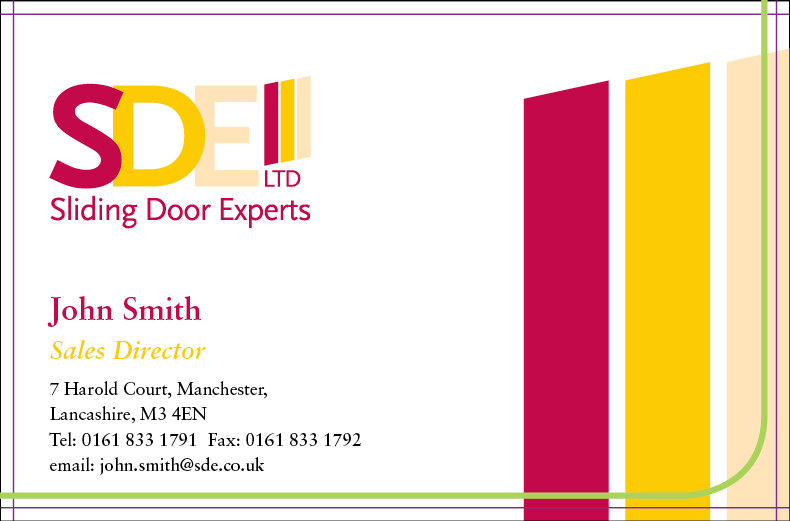

Business Card Example

Here’s an example of a business card, you’d set your page size as 88x58mm. We’ll trim down to approximately 85x55mm.

.png)

-

It’s also good practice to leave a ‘Quiet Zone’ (or safe area) of 4 mm from the trim edge (that’s 5.5 mm or 11.5 mm from the page edge).

The same goes for any folds or creases. Avoid placing any important objects such as text or logos within this quiet zone. This will make your job look more professional and ensure objects don’t look like they’re about to fall off the edge.

Diagram of bleed and quiet zone

Crop Marks and Colour Bars

We don’t require the normal colour bars and crop marks that printers use, so remember not to include them on your PDF.

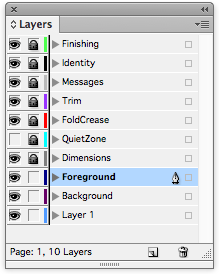

Checking your quiet zone and bleed

Allowing for the correct bleed and quiet zone are really, really

important and they are some of the most common file supply errors

that we see. Here are a few examples of how to get it right (and wrong!):

When viewing your Online Proof the QuietZone is indicated with Red and White Guides. The Bleed is highlighted in Grey.

Objects that enroach our recommended QuietZones may appear closer to the edge than expected once printed.

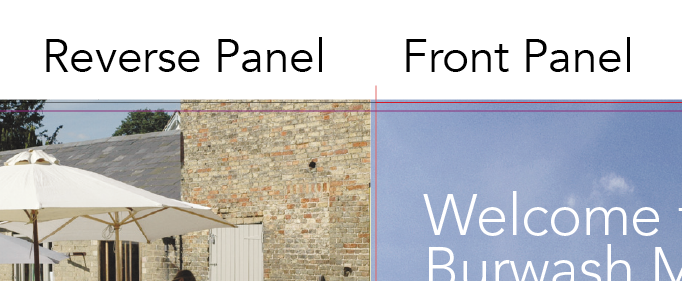

Correct artwork orientation

Always choose a template appropriate to the orientation of your design; it’s best to have text reading ‘upright’ on screen.

If it’s not possible to design the text ‘upright’ (maybe, you need a landscape front and a portrait reverse), then you must ensure the generated artwork’s front and reverse are oriented as you need.

The following examples show how your files need to be supplied, in order for them to print with the correct orientation:

Do not submit one landscape and one portrait side. Instead, rotate the artwork of one of the sides to conform to one of the examples shown here – make it fit a standard template.

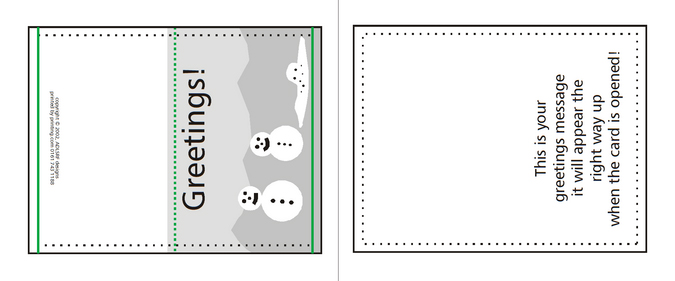

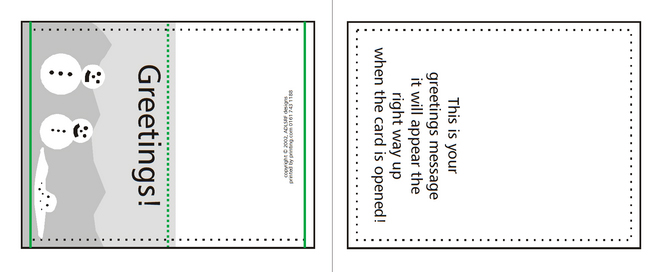

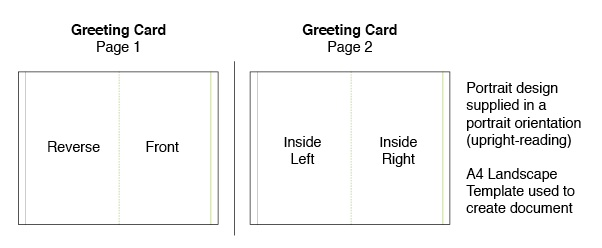

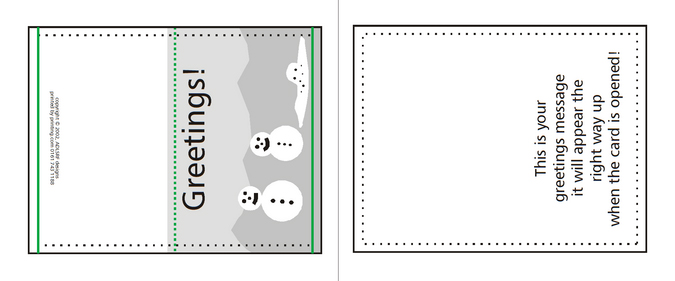

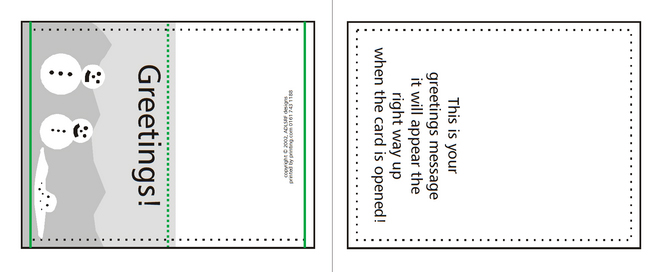

Greeting Cards, Folded Business Cards and Folded Leaflets/Flyers

Be sure to check in the special case of ‘Greetings Cards’ products, especially the inside orientation of landscape cards.

As we impose from left-to-right, the message inside will print on the panel opposite to the reverse. Your files if set up correctly should look like this (the recommended option):

You can also supply like this:

Or like this:

Your Portrait Greeting Cards will look like this:

Common Sizes

Here are the common metric page sizes.

.jpg)

About colour

Contents

-

- Converting to CMYK

-

- Getting the best from CMYK

- Colour Tolerances

- Ink Levels

About CMYK (process) colour

Your computer, scanner, digital camera and monitor create images using combinations of just three "RGB" colours:

Printing presses use four different colours to print these images:

- Cyan (light blue),

- Magenta (pinky-red),

- Yellow, and

- Black

This set of inks is known as "CMYK ", or "process colour".

Converting to CMYK

At some stage of production, RGB images and colours must be converted to CMYK.

Your PDF file needs to be supplied in CMYK process colour, not RGB, Index or as Spot Colours. We can do the conversion for you to CMYK, but you will have more control of it if you manage the conversion before creating your PDF.

When converting to CMYK, it's important to be aware that some RGB and Spot Colours don’t have a direct CMYK conversion. As such, some colour shift may occur.

Conversions on images from RGB to CMYK are best done using software such as Photoshop and you should do this before sending your file to us.

If you don’t perform the conversion yourself, our process will apply an industry-standard profile RGB to CMYK conversion meaning that colours may not print as expected.

Screen versus Print

Due to the differences between a computer screen and a printed item, what you see on your screen may be different from your printed product. This is because computer screens have a light showing from behind them whereas paper doesn't.

Be careful with colour

To create a good solid black, use rich black instead (see Getting the most from Black for more details).

Don’t use four-colour black and it’s best to avoid solid colours of only one ink (i.e. pure cyan, magenta, yellow or black) as these can be susceptible to slight “banding”. Using rich black avoids banding.

You’ll get the best reproduction from colours that are made up of one or two inks (i.e. magenta and cyan etc).

When using lighter shades, avoid tints that contain less than 5% of either Cyan, Magenta, Yellow or Black, as they usually print much lighter than they appear on-screen and you may be disappointed with the outcome. For best results, use tints containing 5% to 30%.

Getting the best from CMYK

Try to avoid large areas of the same colour – this is where colour issues (banding, ghosting etc.) becomes most noticeable. Try to break up large areas of colour with alternate elements or add a background image.

Vignettes or gradient fills are best avoided – they have a tendency to show ‘banding’ and look unprofessional. The Adobe® website offers some advice on gradients if you wish to use them.

Colour Tolerances

You can produce fantastic results with full colour process, and without breaking the bank. It pays to bear in mind that colour variation is inherent in any print process and you shouldn’t expect a perfect match to your chosen colour.

The examples below will give you an idea of how your chosen colour may actually look when printed. We’d be delighted to explain this in more detail – just ask.

Ink Levels

To get the most from your print, we've set some recommended maximum ink levels:

- For coated papers (such as business cards, flyers and leaflets), we recommend a maximum of 300% total ink coverage,

- For uncoated papers, we recommend a maximum of 225%.

More information on ink levels can be found in Avoiding Set Off.

Using images

To optimise your images you'll need to consider the final size your images will be used at. Photographs should be 300-350dpi at the size you are going to use them. There’s no point taking a postage stamp sized image at 300dpi and then blowing it up to a A4 size. Conversely, photographs at more than 350dpi will have no effect on the actual printed quality and will unnecessarily increase file size and

processing time.

Image settings for best results

- All images should be converted to CMYK, and then saved as psd TIFF or JPEG files;

- Photos should be scanned at 300dpi at 100% size;

- Line-art images should be scanned at 800 to 1200dpi at

100% size;

- TIFF and EPS files are saved without any image compression (not JPEG, LZW or ASCII encoded);

- Any extra alpha channels are removed;

- Ink coverage below total ink limit.

Photoshop psd files

Adobe Photoshop psd files can be used in your PDF file, but you will need to save the PDF as a version 1.4 PDF or later. If you are saving as a version 1.3 PDF then you will need to flatten the images when your PDF is created.

Things to avoid

Today’s graphics applications are incredibly sophisticated but may contain features that are incompatible with the latest developments in printing technology.

Likewise, some things can look great on screen, but not when printed.

Based on our experience, we’ve prepared a list of features we know can cause problems.

Contents

- Hairlines

- Texture and Postscript fills

- Layer effects and transparency effects

- Overprint

- Duotone/RGB images

- Borders

- Gradients

- Watermarks

- Aligning elements to folds

Hairlines

Hairlines are ‘device-dependent’ - this means that they print at different resolutions on different machines. They may print reasonably well on your 300dpi laser printer but will disappear on our 2400dpi plate-setter. Use 0.25pt stroke weight instead.

Hairlines are ‘device-dependent’ - this means that they print at different resolutions on different machines. They may print reasonably well on your 300dpi laser printer but will disappear on our 2400dpi plate-setter. Use 0.25pt stroke weight instead.

Texture and Postscript fills

These print erratically so it's best to save them as a TIF or JPG instead.

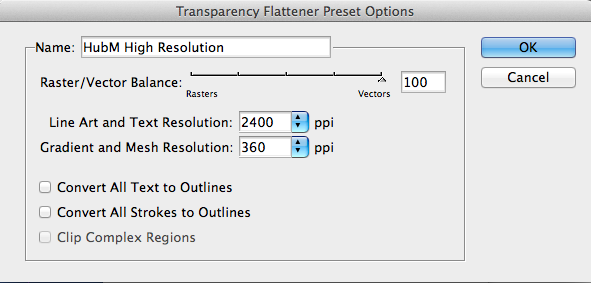

Layer effects and transparency effects

If you are using layer and transparency effects in your artwork, you'll need to supply your PDF as version 1.4 - this will ensure that any layer and transparency effects are honoured.

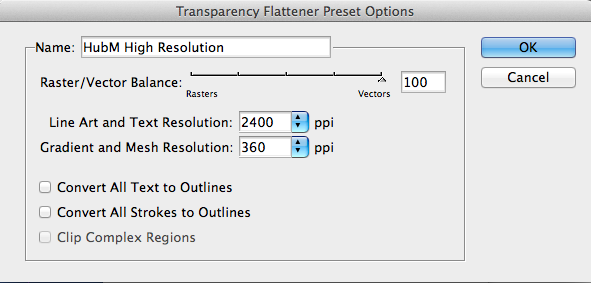

If you are saving as a version 1.3 PDF then your Transparency Flattener preset (in both InDesign® and Illustrator®) will need to be set on High Resolution setting ready for printing and applied again when creating/saving your PDF:

When working in Illustrator®, the Raster Effects Settings will also need to be set to vector:

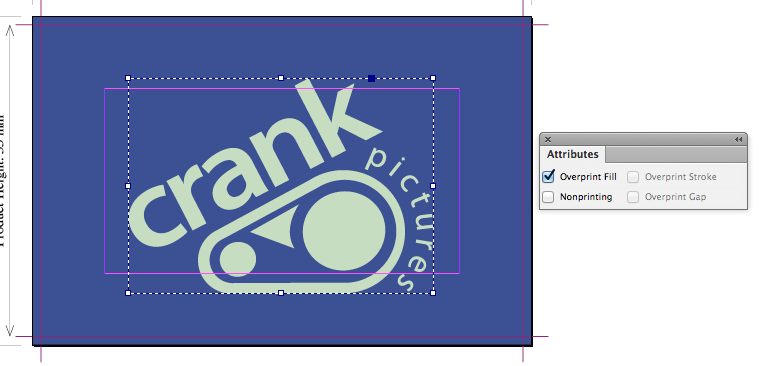

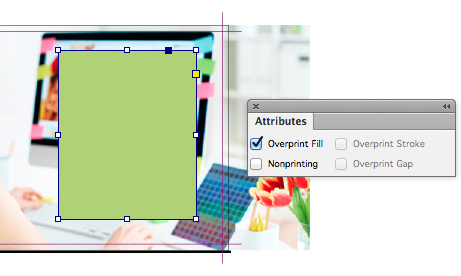

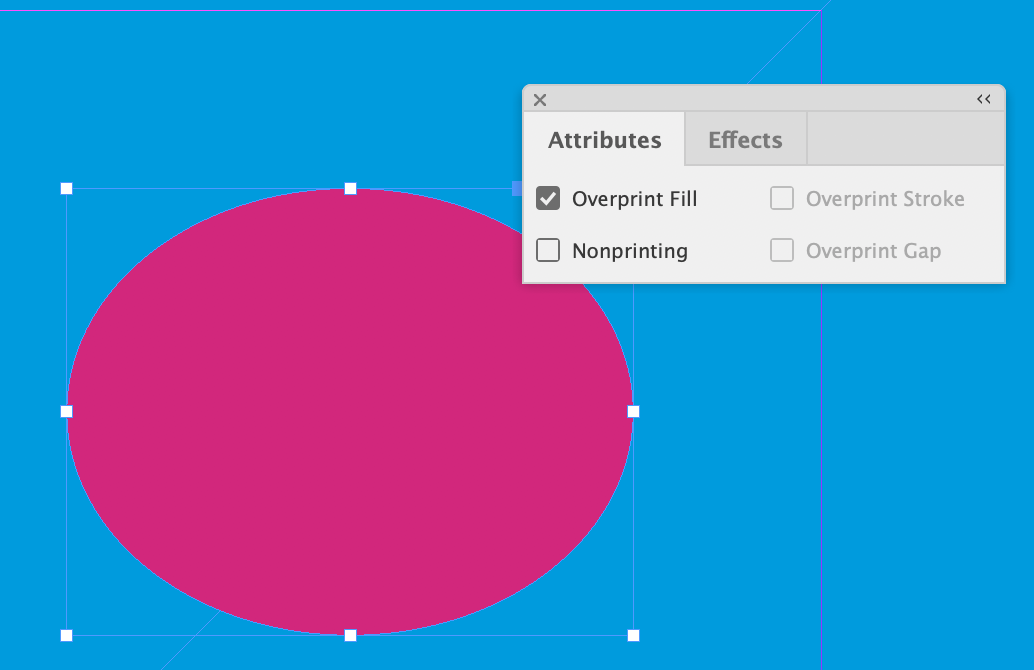

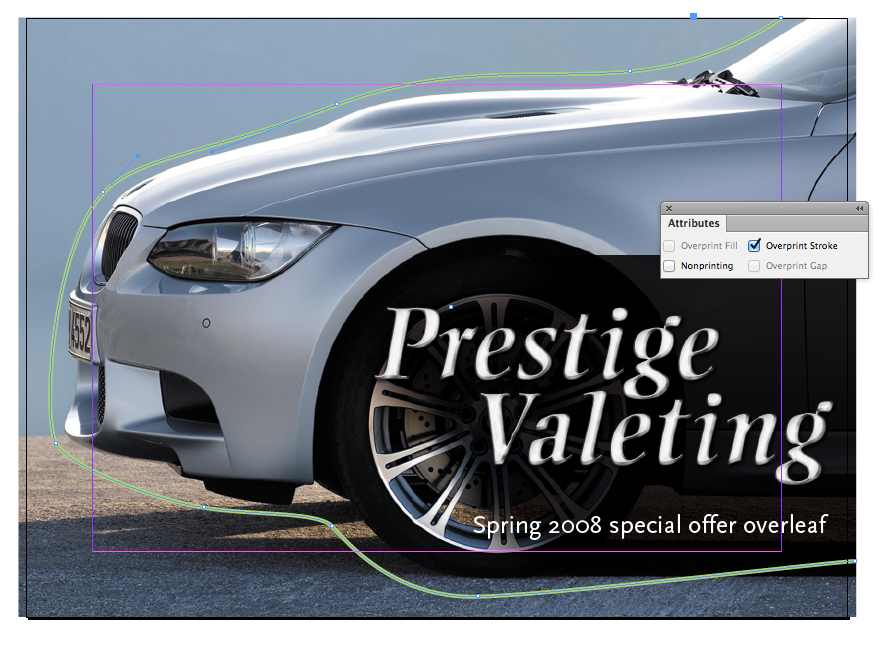

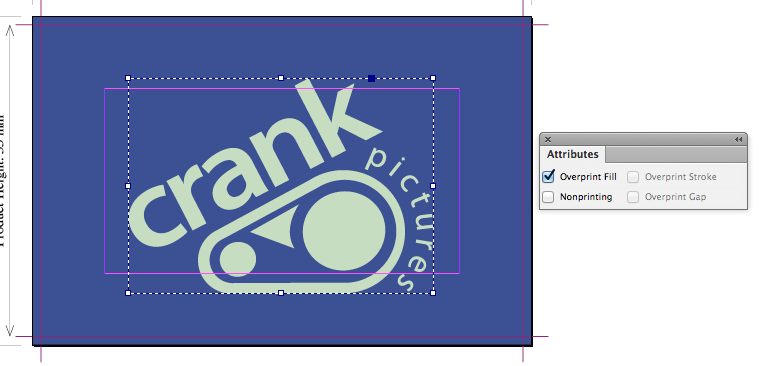

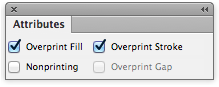

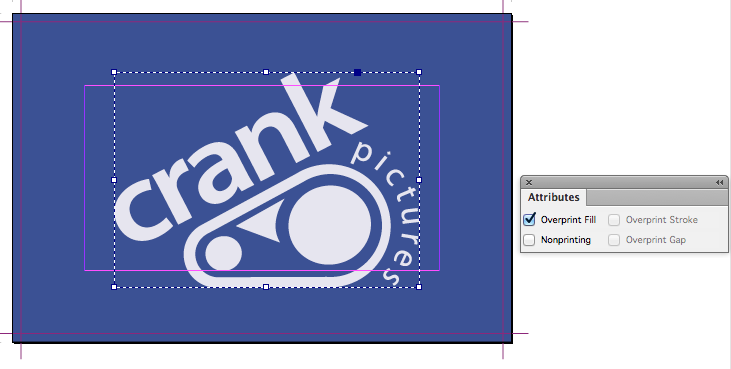

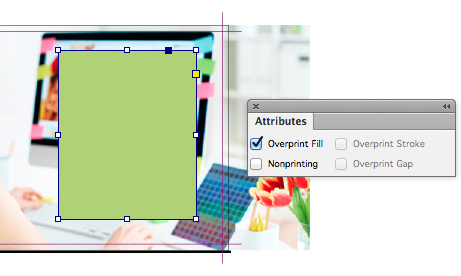

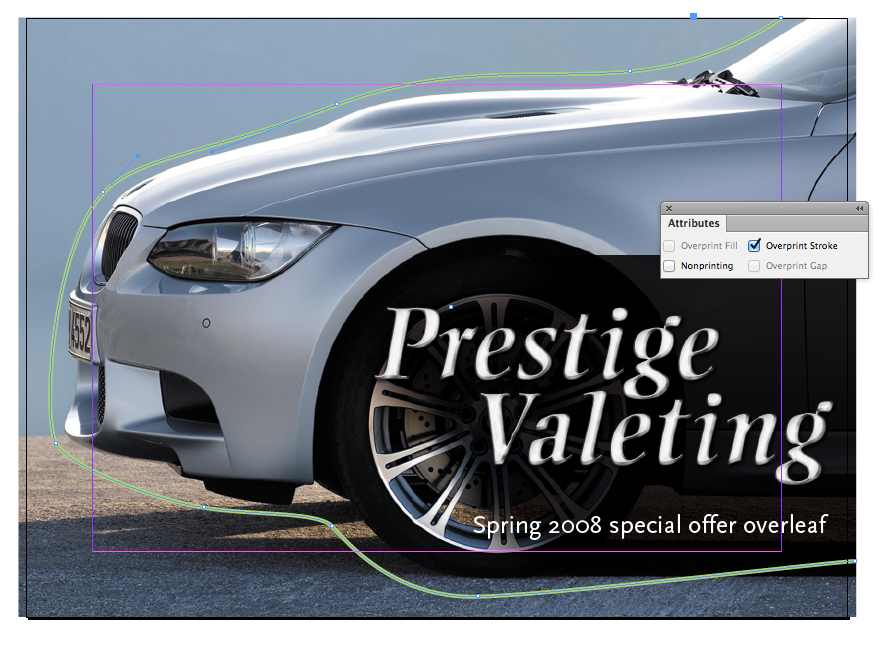

Overprint

Be careful with overprint settings (especially in QuarkXpress). If you set objects to overprint, they won't ‘knock out’ the background and will look very different to what you see on screen or proof.

Be careful with overprint settings (especially in QuarkXpress). If you set objects to overprint, they won't ‘knock out’ the background and will look very different to what you see on screen or proof.

Black text generally defaults to overprint as does the 100% black swatch in some applications (both of which are almost always fine). Please refer to your application manual for more details.

Duotone/RGB images

These may print in black and white or with washed-out colours – you should always convert your artwork to CMYK first.

These may print in black and white or with washed-out colours – you should always convert your artwork to CMYK first.

Borders

Movement during the guillotining process is inherent (NB -/+ 1mm for litho, -/+ 2mm for digital) and you should not expect the space between a border and the finished guillotined edge to be the same on every edge.

Movement during the guillotining process is inherent (NB -/+ 1mm for litho, -/+ 2mm for digital) and you should not expect the space between a border and the finished guillotined edge to be the same on every edge.

Even half a millimetre of movement can be noticeable, especially on smaller products like business cards, and can lead to an uneven/unprofessional look to the artwork.

Gradients

Vignettes or gradient fills are best avoided – these are difficult to print and they have a tendency to show ‘banding’ and look unprofessional. The Help sections on the Adobe website which you may find useful:

Vignettes or gradient fills are best avoided – these are difficult to print and they have a tendency to show ‘banding’ and look unprofessional. The Help sections on the Adobe website which you may find useful:

Indesign (click here), Illustrator (click here) and Photoshop (click here).

Watermarks

Be careful with using watermarks as they can make text or writing difficult to read if you've used too much ink. We cannot guarantee that ink below 5% will appear on the final output so we recommend using a tint between 5% and 7% for best results.

Be careful with using watermarks as they can make text or writing difficult to read if you've used too much ink. We cannot guarantee that ink below 5% will appear on the final output so we recommend using a tint between 5% and 7% for best results.

Aligning elements to folds

Avoid trying to line up design elements with folds or creases. There’s a chance they may not land perfectly on the fold or crease and this can look unprofessional.

Avoid trying to line up design elements with folds or creases. There’s a chance they may not land perfectly on the fold or crease and this can look unprofessional.

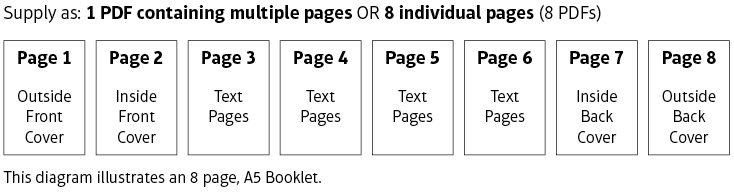

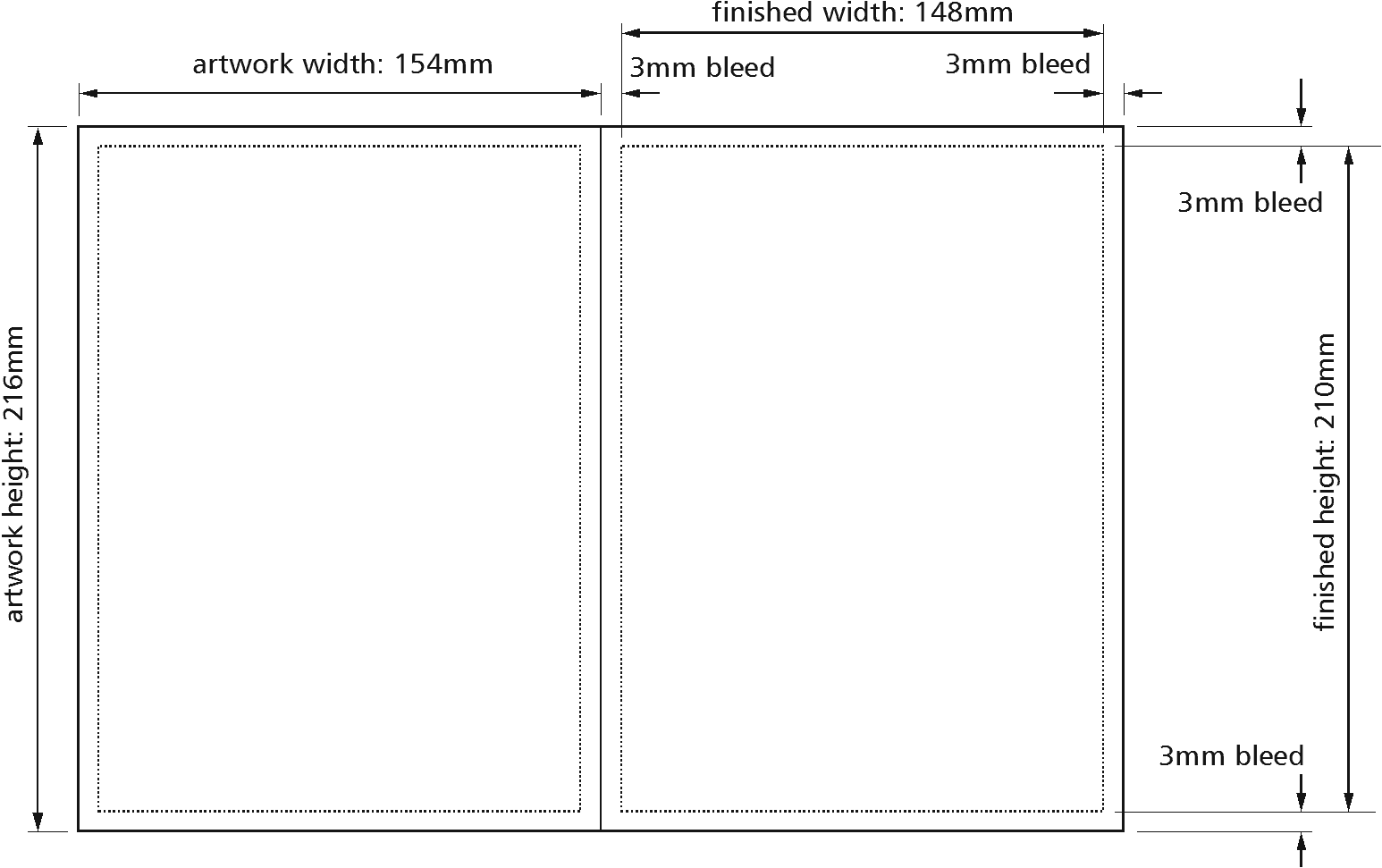

How to supply a booklet

Booklet Templates

Download the appropriate InDesign Template to start your design from.

If you have any questions then it’s best to call us before you start work – it may save you some headaches later on.

TL:DR

- Design as single pages

- 3mm bleed on each page edge

- 10mm 'Quiet zone'

- Avoid design elements that cross the spine

- Avoid using borders in your design

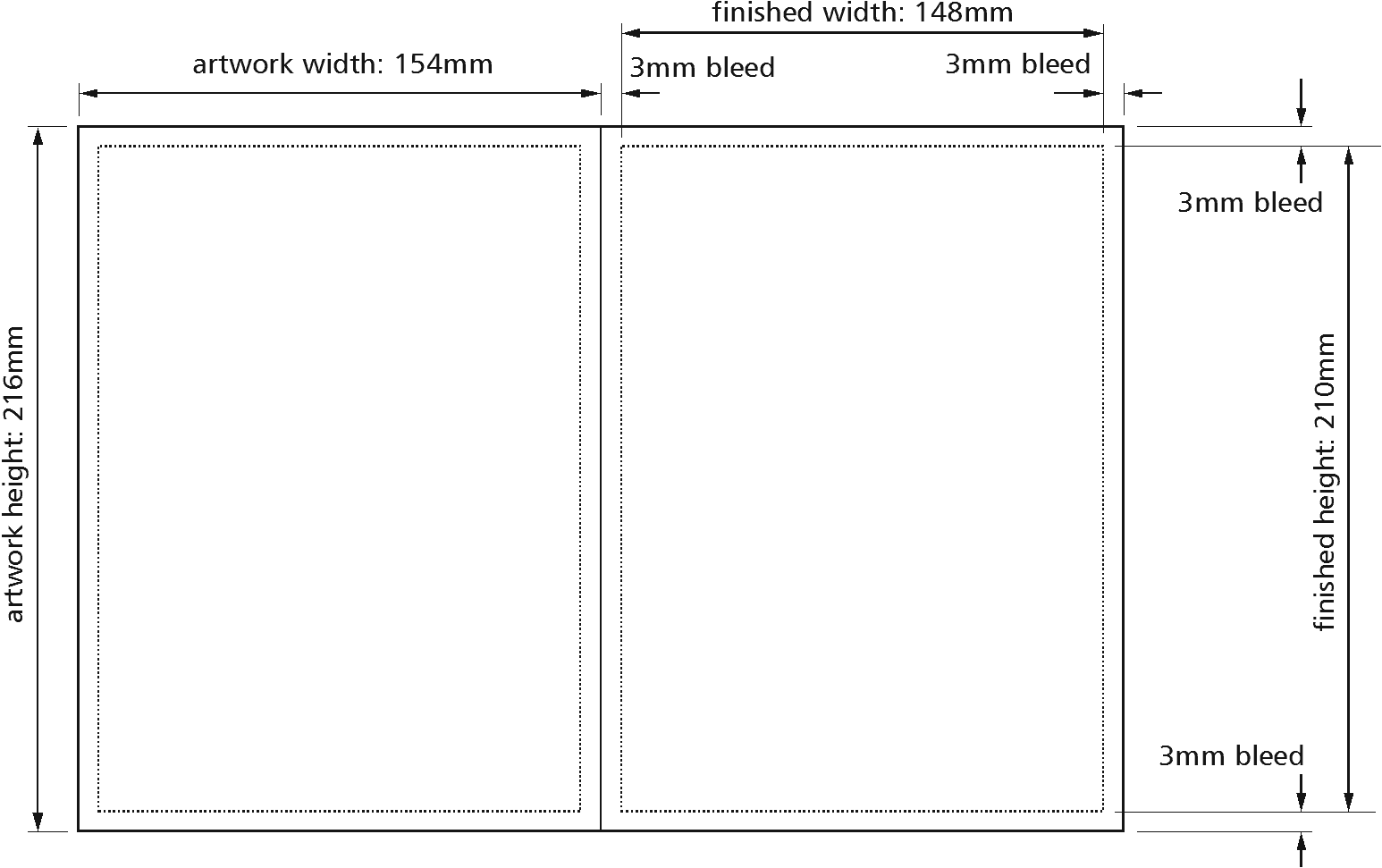

Booklet sizes

| Booklet finished size |

Artwork size (portrait) |

Artwork size (landscape) |

| A3 |

297 mm × 420 mm |

303 mm × 426 mm |

— |

| A4 |

210 mm × 297 mm |

216 mm × 303 mm |

303 mm × 216 mm |

| A5 |

148 mm × 210 mm |

154 mm × 216 mm |

216 mm × 154 mm |

| Square |

210 mm × 210 mm |

216 mm × 216 mm |

— |

| Wide |

244 mm × 210 mm |

— |

244 mm × 216 mm |

| 1/3rd A4 |

99 mm × 210 mm |

105 mm × 216 mm |

— |

| A6 |

105 mm × 148 mm |

111 mm × 154 mm |

— |

Design as single pages

Create a separate page in your artwork for each page of your Booklet. You can supply as a multi-page document or as one document per page.

Please don’t supply as “printer’s pairs” or spreads.

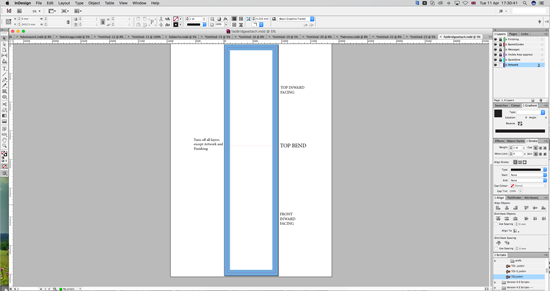

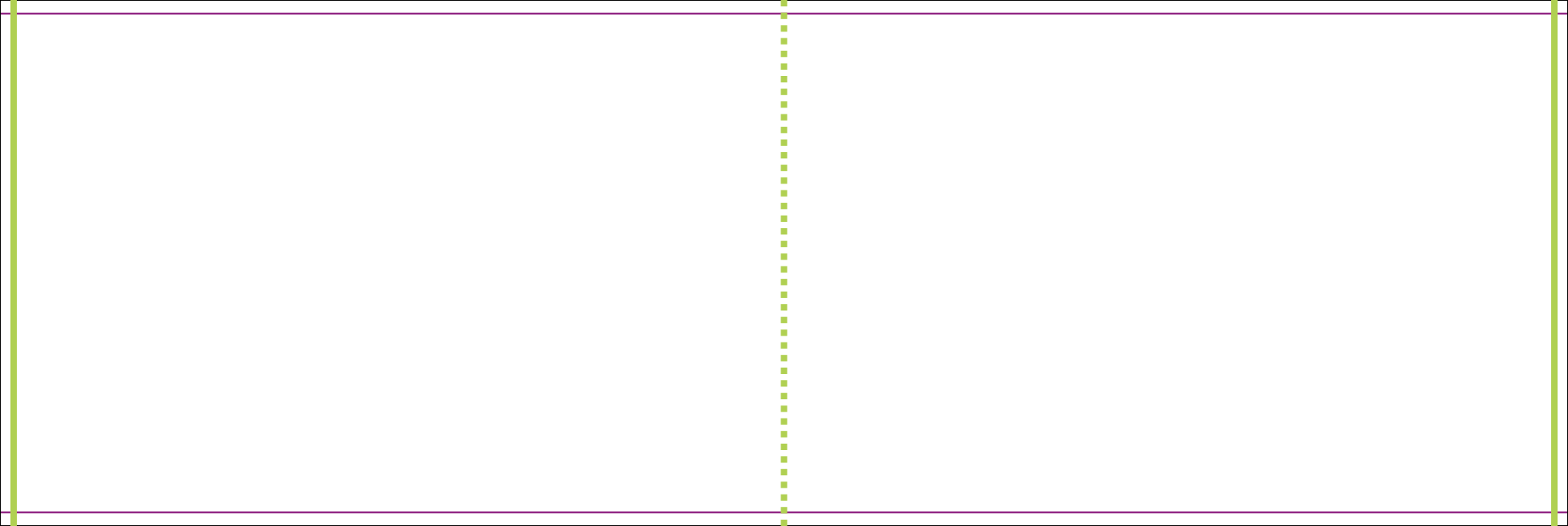

Add 3mm bleed to each side

Booklets need more bleed than other products. Look at the finished page size of the Booklet. Add 3mm to all sides of your page – a total of 6mm across each axis. You even need to add bleed to the edge which forms the spine. Our process chops this off and merges the spine together.

Two pages. Note that they are separate pages, arranged as a spread.

The dotted line shown here (not an artwork item) indicates the finished size of the booklet.

Consistent orientation

Each template has a specific orientation, either landscape or portrait. Don’t change this.

If you want to supply landscape pages on a portrait booklet, just rotate the content of the pages yourself so they fit in the orientation required by the product specification (For example, the back page should be rotated clockwise and the front page and all other pages rotated anti-clockwise). While doing this, pay careful attention to the imposition. Make a mock-up to be safe.

Avoid objects which cross pages

It’s unlikely that objects which cross pages will line up exactly. It’s best to avoid them or accept that there will be some vertical movement throughout your Booklet. You’ll also need to allow for the bleed being trimmed off – ask us if you’re not sure.

If you must have elements that cross the spine, make sure your artwork follows our guidelines for making it work.

Don’t use borders; they’ll look terrible.

.png)

Colours

Avoid trying to match colours throughout the booklet. Some colour variation is inherent in the process and will be most noticeable where two pages of the same colour meet. If you’re ordering a booklet with a thicker cover then it is unlikely that colours crossing from the outer cover to the inner pages will match perfectly due to the different finishes of papers and card types.

Allow for creep

In a stapled Booklet the bulk of the paper causes the inner pages to extend (creep) further out than the outer pages when folded.  When trimmed the inner pages are narrower than the outer pages. The amount of creep is dependent on the number of pages and paper thickness. The thicker the Booklet, the more you need to keep important objects away from the edges.

When trimmed the inner pages are narrower than the outer pages. The amount of creep is dependent on the number of pages and paper thickness. The thicker the Booklet, the more you need to keep important objects away from the edges.

Mind your margins

Normally, we recommend that you keep important objects at least 4mm from the ‘trim’ size. As a result of creep, we’d advise you to increase your margin to avoid anything being chopped off – larger quiet areas are definitely better. When we design Booklets ourselves, we tend to leave at least 10mm of ‘Quiet Zone’ or ‘safe space’ on the trimmed edge. This means that creep isn’t as noticeable and items won’t be chopped off. If your booklet is thicker than 20 pages, we recommend adding 1mm to the quiet zone for each extra 8 pages.

Other booklets

If you are designing a booklet with a folder for a cover, please call us to discuss this as we can give you a special template and specific advice on setting the files up ready for us to produce.

Are you producing your booklet from our Digital Range? If so please read the extra information on our How To supply files for our digital range, as the process for those is different.

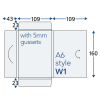

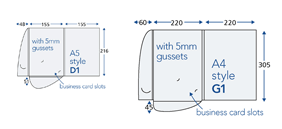

How to supply Presentation Folder files

Folder Templates

Download the appropriate InDesign template to start your design from.

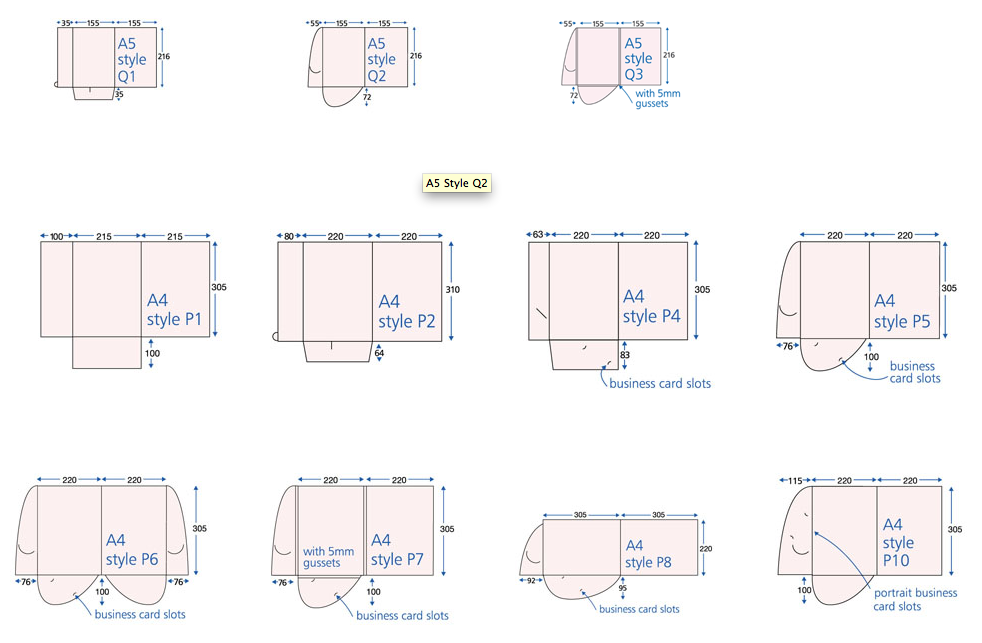

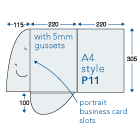

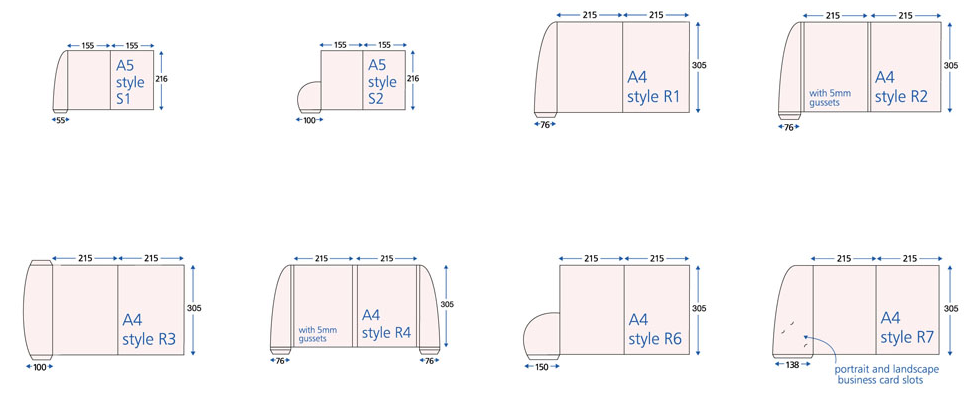

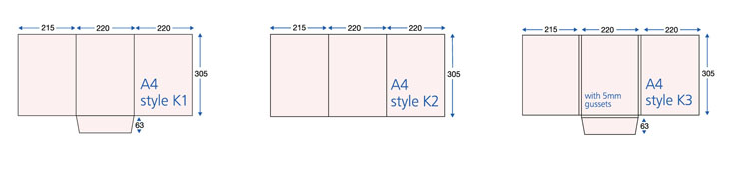

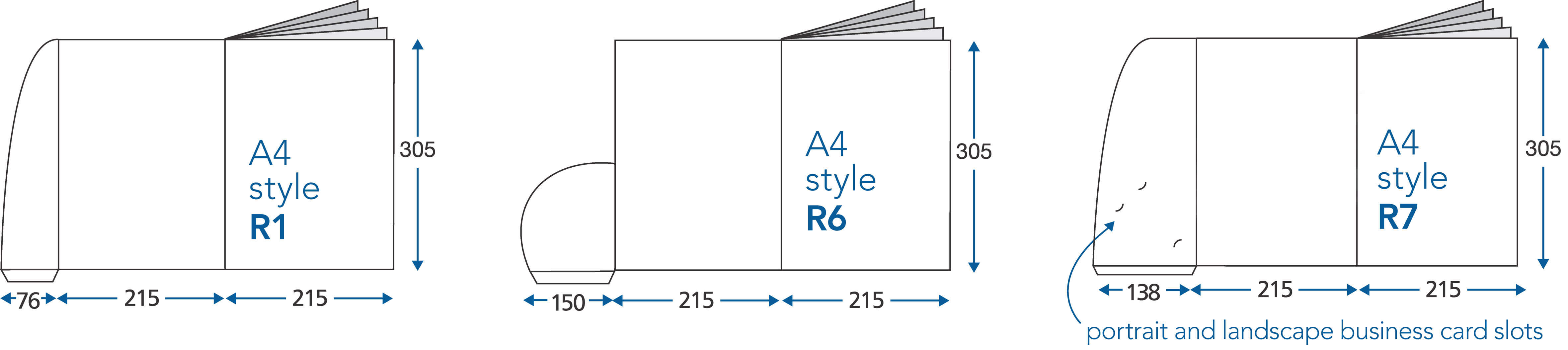

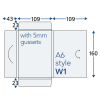

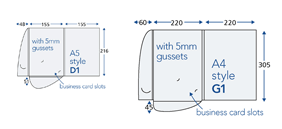

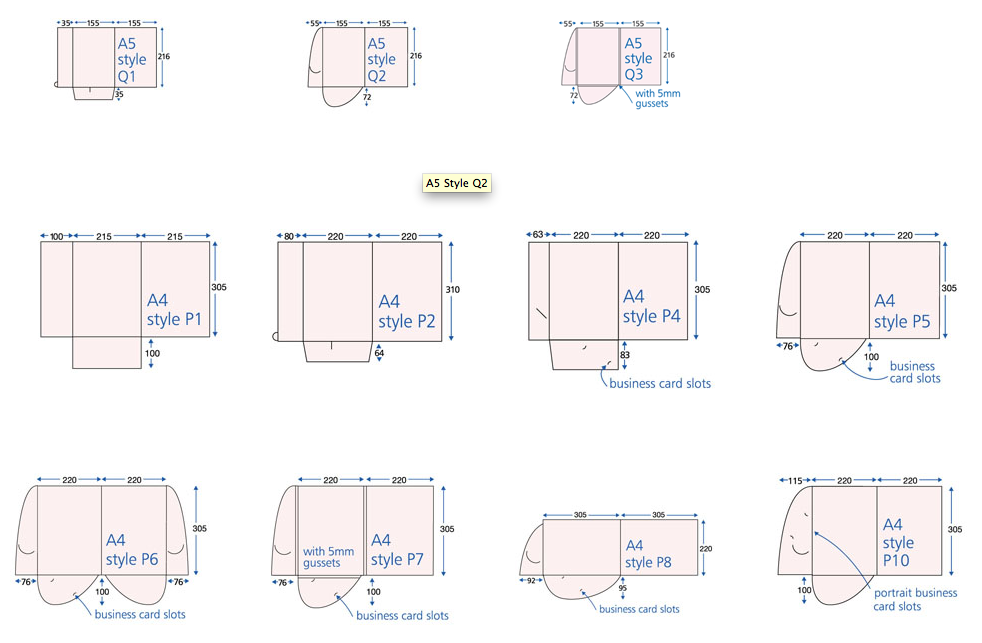

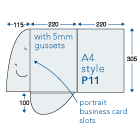

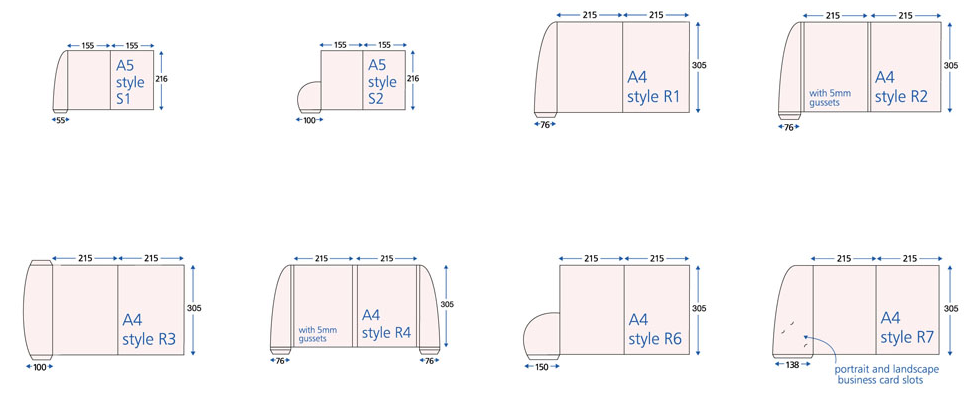

Standard Presentation Folders

The standard Presentation Folders use a standard guide for cutting. We have templates available that you can use to construct your artwork within that match these fixed guides.

If you're using one of our standard folder styles below, then do not modify the cutting lines provided on the template. The artwork also contains an identification panel, e.g. 'Style P2' - this must not be removed or altered in any way.

The styles available are:

450gsm Soft-touch Laminate 2-Panel Interlocking

Soft-touch Folders are available in 3 styles only. They close by interlocking and are supplied flat. Custom style/template is not available on this product.

280gsm/400gsm Standard 2-Panel Interlocking (Presentation)

Interlocking Presentation Folders are available in 12 styles. They close by interlocking (excluding style P1) and are supplied flat.

400gsm Standard Peel and Stick

Peel & Stick Folders are available in 8 styles. They are supplied with Peel & Stick Tape attached and are supplied flat for self assembly.

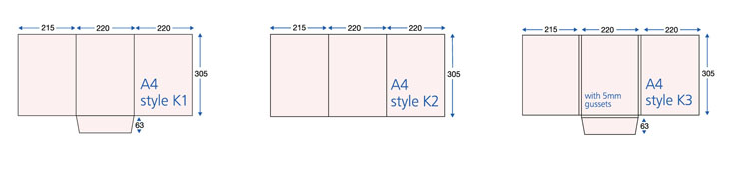

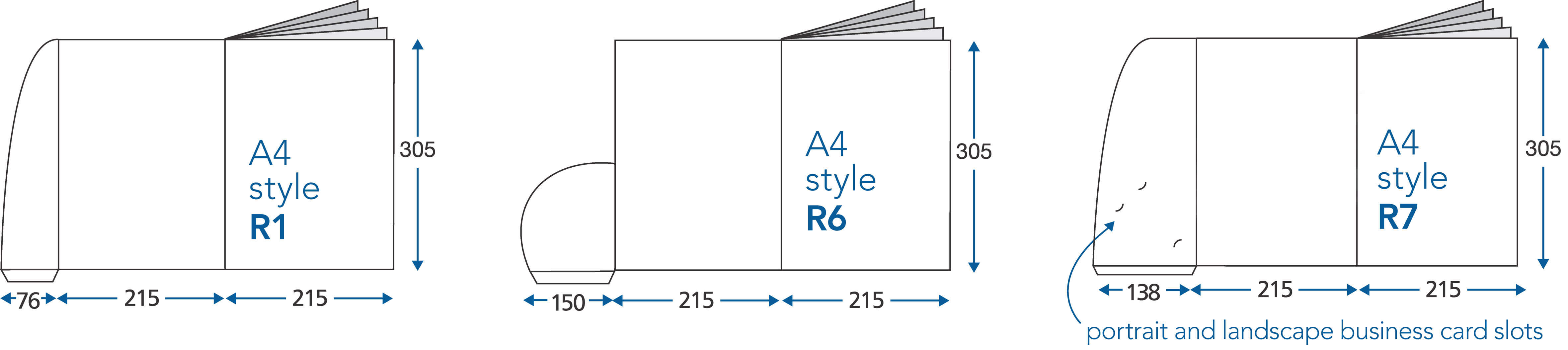

400gsm Standard 3-Panel (Corporate)

3 Panel Folders are available in 3 styles. Styles K1 and K3 have a flap to hold their contents and are supplied flat.

400gsm Booklet Folders

Booklet Folders are available in 3 styles. They hold 4, 8, 12 or 16 text pages (which are stitched in) and include a glued flap/pocket. The are supplied assembled.

250gsm Saver Folders

400gsm Fat Folders (High Capacity)

400gsm Media Folders

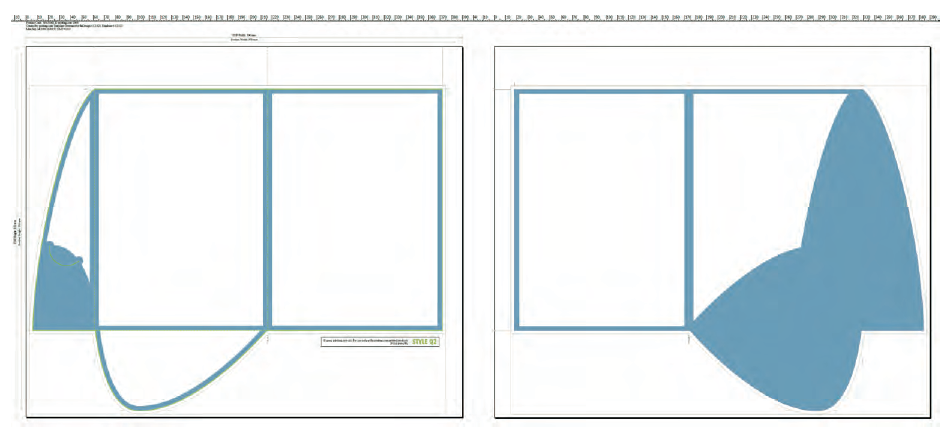

Custom Folders

Please see below if you require a Custom Style for any of the above Folders (Please note that Custom Style is not available on Soft-touch and Saver Folders).

Please note that custom formes will not be archived unless requested - ask for details.

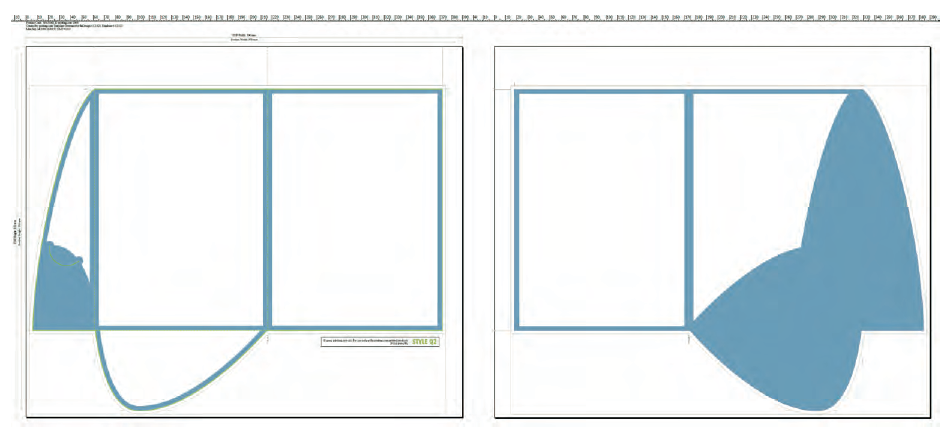

Artwork orientation

Artwork must be supplied‘upright reading,’ i.e. not rotated. The reverse layout must be a mirror image (left to right) of the front layout, as shown below (The blue Quiet Zones show areas hidden by assembly). The cutter guide and template markings are off set on the pages, do not re-centre the artwork.

Use of colour

We'd recommend that you bleed the background of the artwork to the full extent of the template box - this enables better colour consistency across all panels of the folder.

Try to avoid large areas of the same colour or gradients – that’s where colour issues such as banding or ghosting becomes most noticeable. Try to break up large areas of colour with alternate elements or add a background image.

Filling a background

Correct:

Incorrect:

Optional Peel and Stick

Peel and Stick folders must have the ‘tape strip position indicators’ present at every place requiring a tape strip. Our standard templates already include this.

Peel and Stick folders must have the ‘tape strip position indicators’ present at every place requiring a tape strip. Our standard templates already include this.

Custom Folders

We can produce custom folder cutter guides. You'll need to use one of these if you need to adjust any of our standard templates in any way.

Simply supply your Cutter Guide on page 3 of your PDF

It is usually quicker and safer to base your custom design on an Existing Folder Template.

Cuts: 2pt stroke (continouous line)

Creases: 2pt stroke (2pt dash, 2pt gap)

Choose a Product

Use the smallest product that is big enough to contain your artwork, including bleed.

| Product |

Maximum finished size |

| Width |

Height |

| 2-Panel Folders: Holds A5 |

PFA5?X? |

378 mm |

320 mm |

| High Capacity Folder |

FFQ4?CU? |

445 mm |

354 mm |

| 2-Panel Folders: Holds A4 |

PFA4?X? |

608 mm |

415 mm |

| 3-Panel Folders: Holds A4 |

CFA4?X? |

658 mm |

438 mm |

| P8-sized Folder |

PFA4?P8? |

702 mm |

320 mm |

| Presidential Folder |

PRA4? |

870 mm |

378 mm |

Test your artwork in the template in InDesign, before committing a quote to your customer.

Limitations of the forme

Parallel creases, i.e. on a folder with extra capacity or a gusset, must be at least 5 mm from each other.

For gussets larger than 5 mm, use dimensions rounded to the nearest 1 mm, so 6 mm, 7 mm, 8 mm and so on.

Ensure that creases are no less than 5mm away from a parallel die-cut line.

Complexity and anchor points

| Type |

Maximum Forme Anchor Points |

| A5 Folders (2-Panel) |

23 |

| A4 Folders (2-Panel) |

30 |

| Media Folders |

30 |

| Corporate Folders (3-Panel) |

30 |

| Presidential Folders |

30 |

More complicated than that?

If your design exceeds these limits, email a PDF of the forme only for an assessment of additional costs and turnaround (we will endeavour to inform you of any delays in replying), which we will add on your approval.

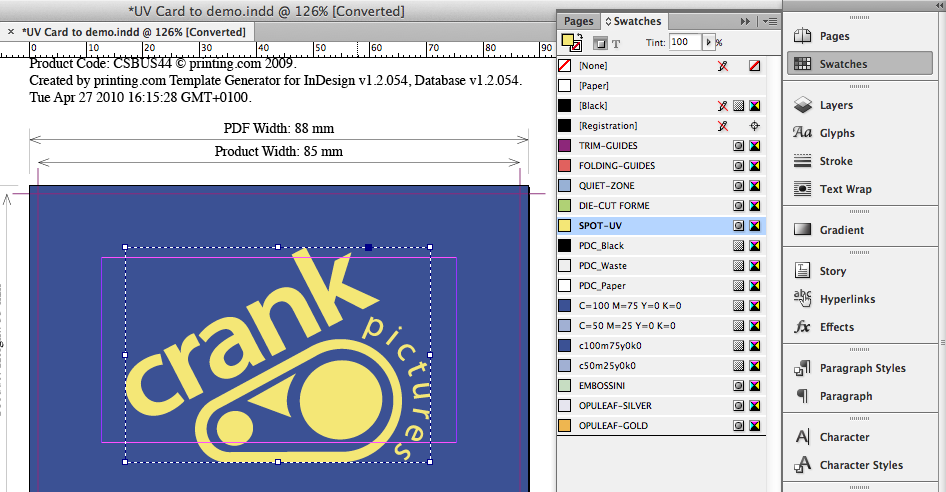

How to supply Spot UV files

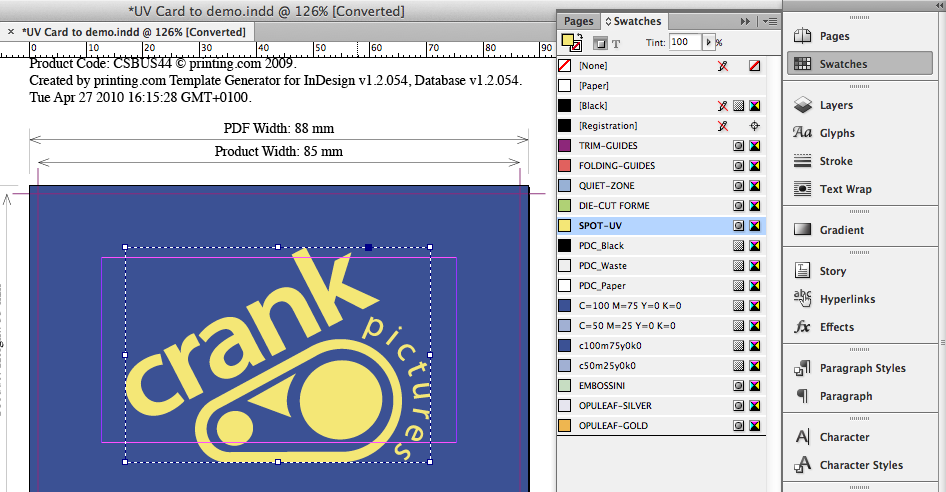

Selected products have an option to add a Spot UV clear varnish shape onto the areas that you mark with a special finishing swatch. This swatch is available in our templates.

Artwork must be supplied containing a layer indicating the areas to be spot UV using the correct colour swatch.

For products with Spot UV on one side, artwork should be supplied on the first file uploaded or the first page of a 2 page PDF. For example: Page/file 1: (front) Artwork containing spot UV & printed design, Page 2: (reverse) Artwork containing printed design.

Artwork supplied incorrectly may lead to delays with sending your order to print.

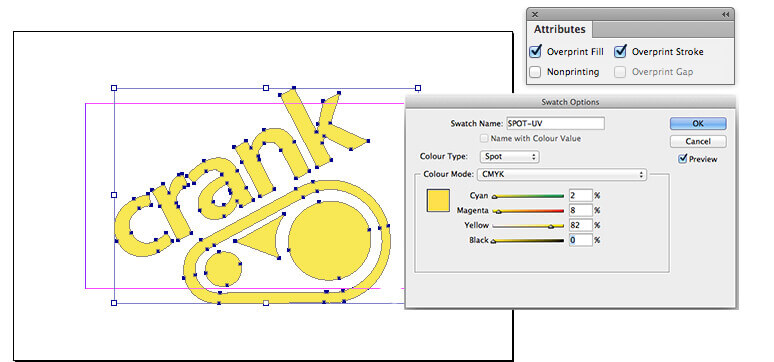

How to supply your Spot UV elements

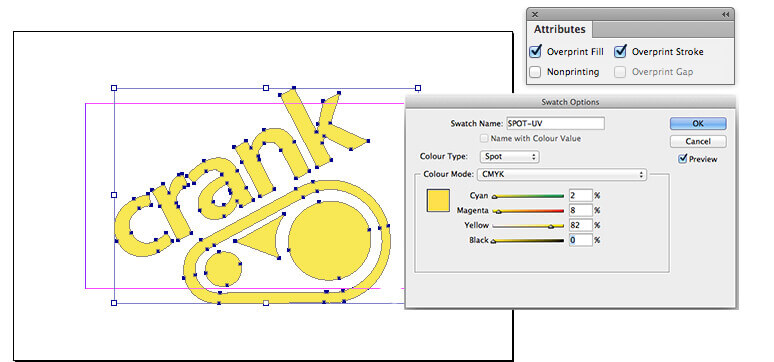

All of our InDesign templates include specific colour swatches for all finishing options or use the instructions below to set up the 'SPOT-UV' spot colour yourself:

- Create a New Colour Swatch in InDesign.

- Name the swatch SPOT-UV

- Set Colour Type to Spot

- Set Colour Mode to CMYK

- Colour Make-up is 2% Cyan, 8% Magenta and 82% Yellow

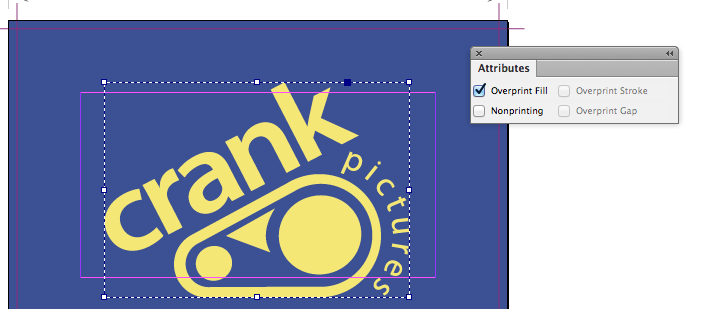

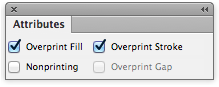

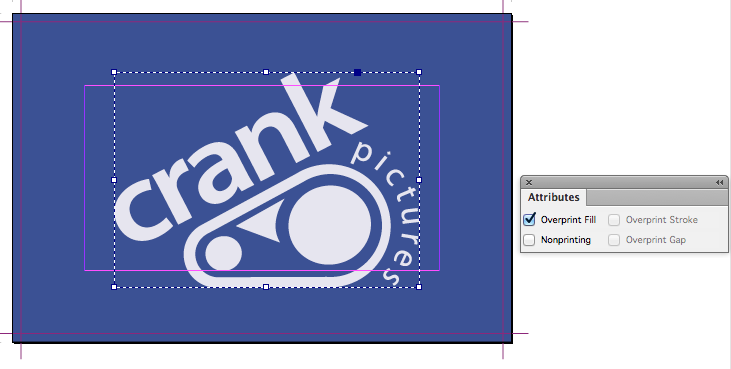

- Set swatch to Overprint ()

How to add the Spot UV to your artwork

-

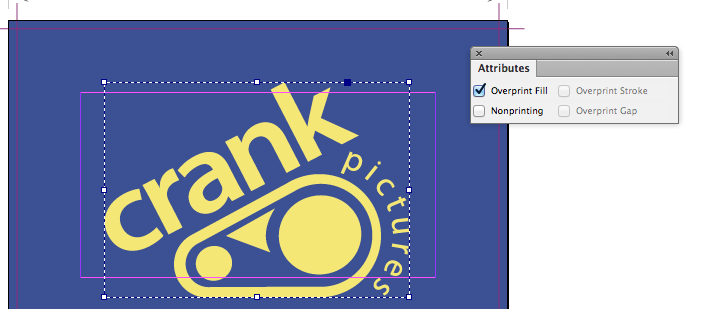

Place Spot-UV elements above your artwork using the special Spot-UV spot colour swatch. This swatch must remain as a spot colour and must not be adjusted in any way. Do not overlay white shapes over the top of the Spot UV elements.

-

Set the Spot-UV elements to Overprint from within your design application.

-

Keep creases and cuts at least 2 mm away from Spot-UV elements.

-

Only use Spot-UV elements on the front pages of your artwork, unless you're making artwork for a double sided Spot UV product.

Limitations: Getting the most from Spot UV

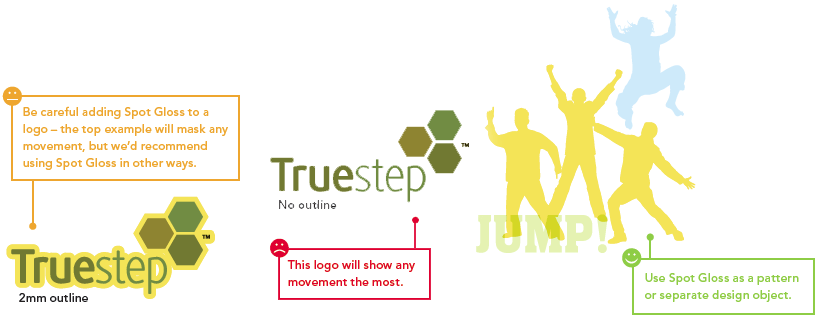

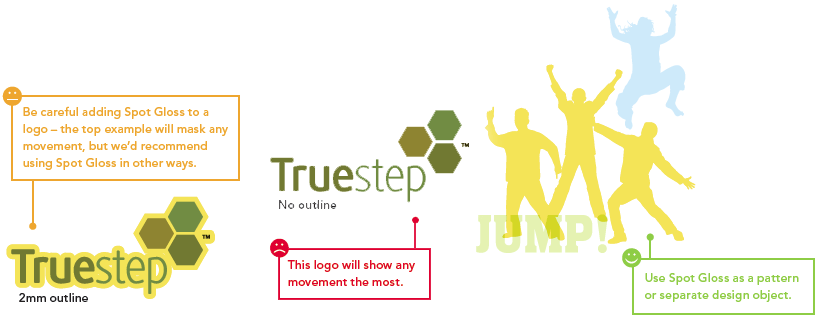

Design with a little tolerance for mis-registration

The UV varnish is applied using a screen printing process, and registration with print can vary by ±2 mm. This means you should expect the Spot UV element to move around the page by up to ±2 mm.

If you are aiming to cover a printed shape having a hard edge, then the Spot UV shape should overlap the printed edge by 2 mm to allow for any inherent variations in registration. Likewise, block shapes meeting the edge should be treated like backgrounds: bleed them to the very edge of the document page, and respect the Quiet Zone.

Don't try to align fine detail

Spot UV is not suited to alignment with fine detail, such as small type, or shapes with thin lines.

Our rule of thumb:

- avoid positive lines thinner than 1 mm, and

- avoid reversed-out lines thinner than 2 mm.

You’ll get best results when you don’t try to match the Spot UV to printed objects, and instead treat it as a design element in its own right.

Seperate Spot UV elements should have a minimum spacing of 2mm. Placing elements too close to each other will result in them becoming one shape and filling in.

Avoid large Spot UV areas over the edge

Avoid large solid areas of Spot UV bleeding to the edge as chipping and flaking may occur once the job has been guillotined or die-cut.

Vectors only for Spot UV

Spot UV elements must be supplied in vector format; any text shapes to be spot-varnished must be converted to paths/outlines.

Check the minimum thickness on text elements

Remember to:

- avoid positive lines thinner than 1 mm, and

- avoid reversed-out lines thinner than 2 mm.

That includes the counters, stroke width and serifs on fonts.

Solid varnish only; no tints

Spot UV cannot be specified as a gradient or tint, i.e. a changing tint from 100% to 0% over an area of artwork.

Samples

We have produced some printed samples that demonstrate how to use Spot UV, ask us for your free copies.

Quick File Check

After following the recommendations above check the following:

SPOT-UV artwork in on the topmost layer:

SPOT-UV artwork is set to Overprint:

SPOT-UV Swatch is set up correctly:

SPOT-UV Swatch shows in Adobe Acrobat's Output Preview:

SPOT-UV Swatch shows in Adobe Acrobat's Output Preview:

SPOT-UV colour is transparent when Simulate Overprint is selected in Output Preview:

SPOT-UV colour is yellow when Simulate Overpint is NOT selected:

SPOT-UV colour is highlighted when Show Overprint is selected:

How to supply Embossed files

Certain products have an option to add an embossed area to your design. You indicate this by using a special finishing swatch. This swatch is available in our templates, please ask for a copy before starting your design.

How to supply your Embossed elements

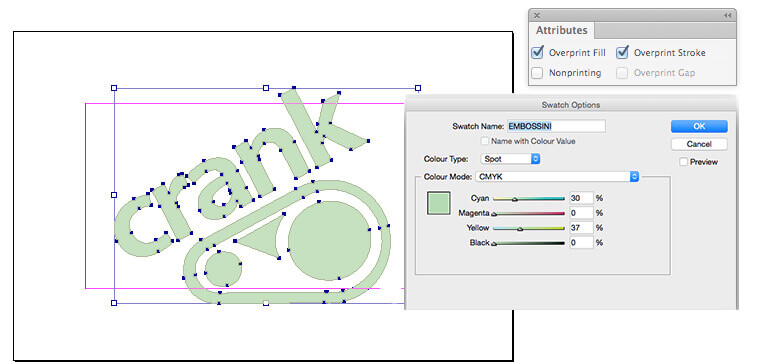

All of our InDesign templates include specific colour swatches for all finishing options or use the instructions below to set up the EMBOSSINI spot colour yourself:

- Create a New Colour Swatch in InDesign.

- Name the swatch 'EMBOSSINI' (must be exact)

- Set Colour Type to Spot

- Set Colour Mode to CMYK

- Colour Make-up is 30% Cyan and 37% Yellow

- Set swatch to Overprint ()

How to add the Embossing to your artwork

-

Place the Embossing elements above your artwork using the special EMBOSSINI spot colour swatch. This swatch must remain as a spot colour and must not be adjusted in any way.

-

Set the EMBOSSINI elements to Overprint from within your design application.

-

Avoid having areas of embossing bleeding to the edge as chipping, flaking and flattening of the embossed area may occur when the job is guillotined.

-

Only add embossed elements on the front page of your artwork.

Obtaining the EMBOSSINI swatch

This swatch is available in our templates, please ask for a copy before starting your design.

Limitations: Getting the most from Embossing

Design with a little tolerance for mis-registration

The embossing is applied using by applying pressure from the reverse with a die and stretching the fibres of the paper. This means that the registration with print can vary by ±1 mm. This means you should expect the embossed element to move around the page by up to ±1mm.

If you are aiming to cover a printed shape having a hard edge, then the embossed area should overlap the printed edge by 1 mm to allow for any inherent variations in registration.

Don't try to align fine detail

Embossing is not suited to alignment with fine detail, such as small type, or shapes with thin lines.

Our rule of thumb:

- avoid positive lines thinner than 1 mm, and

- avoid reversed-out lines thinner than 2 mm.

You’ll get best results when you don’t try to match the embossing to printed objects, and instead treat it as a design element in its own right Seperate embossed elements should have a minimum spacing of 1mm. Placing elements too close to each other will result in them becoming one shape and filling in.

Avoid using embossing on small text. Fine fonts, particularly those with serifs or tapered lines do not produce good results. The thinnest part of the font must be 1mm in width.

Avoid large embossed areas over the page edge

Avoid having areas of embossing bleeding to the edge as chipping, flaking and flattening of the embossed area may occur as the job is guillotined.

Vectors only for embossing

Embossed elements must be supplied in vector format; any text shapes to be spot-varnished must be converted to paths/outlines.

Check the minimum thickness on text elements

Remember to:

- avoid positive lines thinner than 1 mm, and

- avoid reversed-out lines thinner than 2 mm.

That includes the counters, stroke width and serifs on fonts.

Solid Embossing only; no tints

Embossing cannot be specified as a gradient or tint, i.e. a changing tint from 100% to 0% over an area of artwork.

Embossing Depth

Embossing depth cannot be accurately measured. It is a process where the finisher determines the depth based on artwork and paper stock, and then has to continually maintain throughout the run. As a rule pressure will be applied to ensure depth will be as deep as possible without cracking the paper. Embossing on printed areas creates more opportunity for cracking and this cracking will be more noticeable on

dark colours.

Be aware that the reverse of the printed item will be "de-bossed", this may distort the design or text on the reverse.

Samples

Printed samples are available, demonstrating how to use embossing. Ask us for your free copies!

How to supply Foil Blocked files

Certain products have an option to add a foil blocked area to your design. You indicate this by using a special finishing swatch. This swatch is available in our templates, please ask for a copy before starting your design.

How to supply us your areas to be foiled

All of our InDesign templates include specific colour swatches for all finishing options or use the instructions below to set up the OPULEAF-GOLD, OPULEAF-SILVER and OPULEAF-COPPER spot colours yourself:

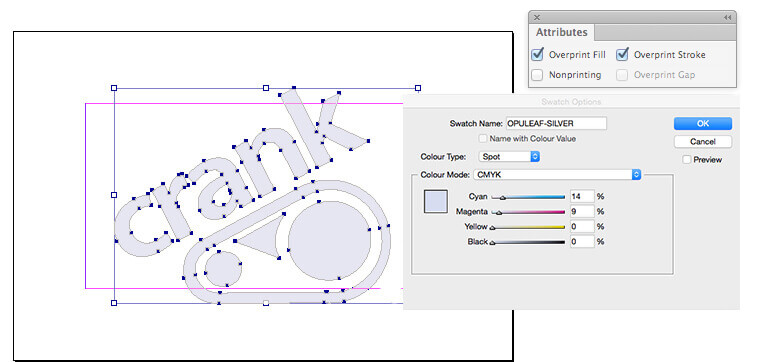

Creating the OPULEAF-SILVER swatch in InDesign/Illustrator

- Create a New Colour Swatch in InDesign.

- Name the swatch 'OPULEAF-SILVER' for silver (must be exact)

- Set Colour Type to Spot

- Set Colour Mode to CMYK

- Colour Make-up is 14% Cyan & 9% Magenta

- Set swatch to Overprint ()

Creating the OPULEAF-GOLD swatch in InDesign/Illustrator

- Create a New Colour Swatch in InDesign.

- Name the swatch 'OPULEAF-GOLD' for gold (must be exact)

- Set Colour Type to Spot

- Set Colour Mode to CMYK

- Colour Make-up is 40% Magenta & 93% Yellow

- Set swatch to Overprint ()

Creating the OPULEAF-COPPER swatch in InDesign/Illustrator

- Create a New Colour Swatch in InDesign.

- Name the swatch 'OPULEAF-COPPER (Must be exact)

- Set Colour Type to Spot

- Set Colour Mode to CMYK

- Colour Make-up is 38% Magenta, 72% Yellow & 28% Black

- Set swatch to Overprint ()

How to add the Foil Blocking to your artwork

-

Place the Foil Blocking elements above your using one of the special Foil Blocking spot colour swatches.

There are 2 swatches available:

- OPULEAF-GOLD for gold foiling

- OPULEAF-SILVER for silver foiling

You can only use one or the other, not both

These swatches must remain as a spot colours and must not be adjusted in any way.

-

Set the OPULEAF-GOLD or OPULEAF-SILVER elements to Overprint from within your design application.

-

Avoid having areas of Foil Blocking bleeding to the edge as chipping and flaking of the foiled area may occur once the job has been guillotined.

-

Only add Foil Blocked elements on the front page of your artwork.

Limitations: Getting the most from Foil Blocking

Design with a little tolerance for mis-registration

Foil stamping or blocking is a process where a solid area of the paper has a silver or gold metallic foil applied by heat and pressure This means that the registration with print can vary by ±1 mm. This means you should expect the Foiled element to move around the page by up to ±1mm.

If you are aiming to cover a printed shape having a hard edge, then the Foiled area should overlap the printed edge by 1 mm to allow for any inherent variations in registration.

Don't try to align fine detail

Foiling is not suited to alignment with fine detail, such as small type, or shapes with thin lines.

Our rule of thumb:

- avoid positive lines thinner than 0.5mm, and

- avoid reversed-out lines thinner than 2 mm.

- 1mm minimum spacing between separate foiled elements.

You’ll get best results when you don’t try to match the Foiling to printed objects, and instead treat it as a design element in its own right. Seperate Foiled elements should have a minimum spacing of 1mm. Placing elements too close to each other will result in them becoming one shape and filling in.

Avoid using Foiling on small text. Fine fonts, particularly those with Serifs or tapered lines do not produce good results. The thinnest part of the font must be 1mm in width.

Avoid large Foiled areas over the page edge

Avoid having areas of Foiling bleeding to the edge as chipping and flaking of the Foiling area may occur once the job has been guillotined.

Vectors only for Foil Blocking

Foil Blocked elements must be supplied in vector format; any text shapes to be spot-varnished must be converted to paths/outlines.

Check the minimum thickness on text elements

Remember to:

- avoid positive lines thinner than 0.5 mm, and

- avoid reversed-out lines thinner than 2 mm.

That includes the counters, stroke width and serifs on fonts.

Solid Foiling only; no tints

Foiling cannot be specified as a gradient or tint, i.e. a changing tint from 100% to 0% over an area of artwork.

Foiling Imprint

The process of foiling leaves a faint cross hatch effect on the reverse of the product where foiling is applied on the front. Foil residue can also be present on the edges of foiled areas. This is inherent in the foiling process.

Samples

We have produced some printed samples that demonstrate how to use Foil blocking, ask us for your free copies.

How to supply folded and perforated leaflets

Folded Leaflet Templates

Download the appropriate InDesign Template to start your design from.

Folded Leaflets

Artwork for Folded Leaflets is the same as regular flat products. The artwork is to be designed 'flat', showing more than one panel per designed page, with essential elements avoiding the folds and edges. You don't need to supply us folding guides for our standard folds - please contact us if you are designing a file that needs custom folding.

Download one of our Folded Leaflet InDesign Templates to base your design on. The fold marks and quiet zones provided in the design templates are to help with design, and do not appear on printable artwork.

File Supply

The outside design should be supplied as page 1 and the inside design as page 2. You can supply two seperate PDF files or 1 PDF with 2 pages.

PDF Page 1 (Outside) PDF Page 2 (Inside)

End Panel, Back Panel, Front Panel Inside Left, Middle, Inside Right

Example of an A4 Folded Leaflet (A4 Roll-Folded to DL)

Our most popular folds

Approved Custom Folds

If you require an Approved Custom Fold from the list below please contact us. Custom Folds carry an additional cost and add 1 working day to your order.

• A2 to A5 - A2 concertina folded to 148x420mm, then half folded to A5.

• A3 to DL - A3 half folded to A4, then roll or Z folded to DL.

• A3 to A5 - A3 landscape half folded to 420x148mm, then half folded to A5 landscape.

• A3 to A6 - 4 panel concertina fold, then half folded to A6.

• A4 to A7 - 4 panel concertina fold, then half folded to A7.

• A4 to 99x105mm - 3 panel roll or concertina fold, then half folded to 99x105mm

• A4 half folded to A5 and half folded again to 74mm x210mm

Prohibited folds

- Gate folds

- Cross fold then half fold (e.g. A2 cross fold, then half fold to A5)

- A1 to A5

- A2 to DL

- A2 to A6

- A5 roll folded

- 6 panel DL Roll Fold - 594x210mm roll folded to 1/3rd A4

- 6 or more Folded Panels (Except 6 Panel DL Concertina Fold)

Supplying Custom Folds

Please supply your files using a 1.5mm bleed. We do not require Crop/Trim Marks or Folding Guides to be present on your artwork, just email us the panel dimensions your require, with the measurements taken from left to right for page 1 only.

For example:

Custom size = 287 x 210mm (290 x 213mm including 1.5mm bleed)

Finished Panel Dimensions = 89mm (End Panel) / 99mm (Middle Panel) / 99mm (Front Panel).

Check panel sizes

A mistake commonly made with Folded Leaflets is to design incorrectly sized panels for the product’s fold type, resulting in the product looking unusual, e.g. short front panels, panels missing their folding line, front-to-back misalignment, and even mixed-up panels. Please ask us for a template to avoid fold alignment issues.

Keep essential elements away from edges and folds

Respect the Quiet Zones by keeping text at least 4mm away from the folds – these Quiet Zones are identified on the Quiet Zone layer of the templates.

‘Front cover panel’ backgrounds

We recommend that ‘Front cover panel’ backgrounds should overlap the fold. When designing Folded Leaflets with a front panel background that is close to the fold, ensure that the picture overlaps the fold by 1 mm. This allows for production tolerances when folding, and prevents a contrasting stripe (from the adjacent reverse panel) from showing on the front face of the finished Folded Leaflet.

We recommend that ‘Front cover panel’ backgrounds should overlap the fold. When designing Folded Leaflets with a front panel background that is close to the fold, ensure that the picture overlaps the fold by 1 mm. This allows for production tolerances when folding, and prevents a contrasting stripe (from the adjacent reverse panel) from showing on the front face of the finished Folded Leaflet.

Cracking

When paper is folded, its interlinking fibres are compressed on one side and stretched on the other. If the outer fibres lose their hold on each other, we see this as 'cracking': an opening out of the paper on the outside. This will be more visually apparent where the design includes a dark colour across the fold. If dark colours are required please upgrade to a Laminated Product which will help to reduce the appearance of cracking. (This also affects Folded Flyers which go through the same process)

Indicate the front panel

To indicate your intended front panel to us, just add a 0.25pt red keyline around the outer three edges of your front cover. This won't be visible once your folded leaflet has been printed.

Create a physical mock-up

We'd recommned that you produce a working mock-up of the design yourself (there is no requirement for this to be sent to us though). This often gives an indication of what makes a well-balanced layout, and might also catch layout errors.

Perforated Folded Leaflets

Folded Leaflets with Easy Tear-off Panel

Some Folded Leaflets can have a perforated easy tear-off panel, the sizes available are: A3, A4, A5, 2 panel DL, 3 panel A5, 3 panel A6, 4 panel A6, and 4 panel DL. Advice on artwork and file supply is the same as Folded Leaflets above.

There are 3 options for the position of the perforation;

- Front panel;

- End panel, or

- In half.

The template below for a 3 panel fold has the front panel as the tear-off panel, indicated by a 0.5pt green dashed line on the page edge.

We have templates available that are specific to Perforated Folded Leaflets, please ask us for a copy.

Perforated Leaflets

Standard perforation positions

Perforated Leaflets are the same as our range of 150gsm Gloss and 170gsm Silk flat Leaflets, but with an added perforation.To indicate your choice of perforation, please add a 0.5pt green dashed line to the page edge.

There are 2 fixed half perforation options available:

- Half Perforation - Parallel to the long edge of the page

- Half Perforation - Parallel to the short edge of the page

.png)

The ‘Half Perf’ options will always be dead centre of the short or long edge. This example on the right shows the green dashed line on the right short side of the page, this will have a perforation applied to the centre of the page parallel to the short edge of the page.

The 1/3rd Perforation is always made parallel to the short edge and is available on A3, A4 and A5. The position of the perforation for each size is:

- A3 Perforated at 140mm from specified short edge

- A4 Perforated at 140mm from specified short edge

- A5 Perforated at 140mm from specified short edge

Custom perforation positions

Please ask us if you want a different position for your perforation.

How to supply files for our digital ranges

There are a few elements that you should consider that are specifically related to our digital printing process. Follow this advice to ensure you get the best possible printed results:

Total Ink Limits

Avoid using colours with a total ink limit over 275%. Any colours exceeding this will be automatically re-mapped to their nearest equivalent so there may be a shift in colour.

Quiet Zone

Where digitally printed items are concerned, bigger IS definitely better – we recommend at least 10mm. Having important elements such as text less than 10mm from the edge may be printed with unexpected results.

Design Elements

Where possible, keep the design simple, lots of white space tends to work well. Large areas of flat colour can be problematic, resulting in an uneven solid that can look banded. A large area is defined as larger than 40mm square.

Using Grey

To achieve neutral shades of grey use black only. It is best to avoid using grey tints below 20% or over 80%. Large areas of grey can appear patchy and uneven - consider adding a texture to help mask this. Greys that are made up of all four CMYK printing channels have a tendency to print unevenly with a yellow cast to them.

Gradients and Blends

Gradients don’t print well, If you must use them, try adding texture or a low amount of noise to ensure a smoother transition from light to dark. Alternatively, limit blends to less than a 50% tint change. Grey tints are less forgiving than other colours. You’ll get better results if you create your blends in a raster based application such as Photoshop®.

Tints

Consider adding texture to any large areas of colour, especially on lighter tints. Avoid using tints below 10% as these are likely to disappear when printed.

Digital Products with specific requirements

Digital Booklets

Thin White Border

If you are designing a booklet to be used on a Thin White Border product then you do not have to add the white border yourself. We will add the border automatically for you. The border that we add

will vary in size depending on the thickness of the booklet. If you do wish to add your own thin white borders then ensure that this is at least 10mm wide.

Creep

When designing your digital booklet you need to allow for creep. Bear in mind that with the Thin White Border products, the thickness of the border will vary throughout the booklet due to the creep being trimmed off.

When designing your digital booklet you need to allow for creep. Bear in mind that with the Thin White Border products, the thickness of the border will vary throughout the booklet due to the creep being trimmed off.

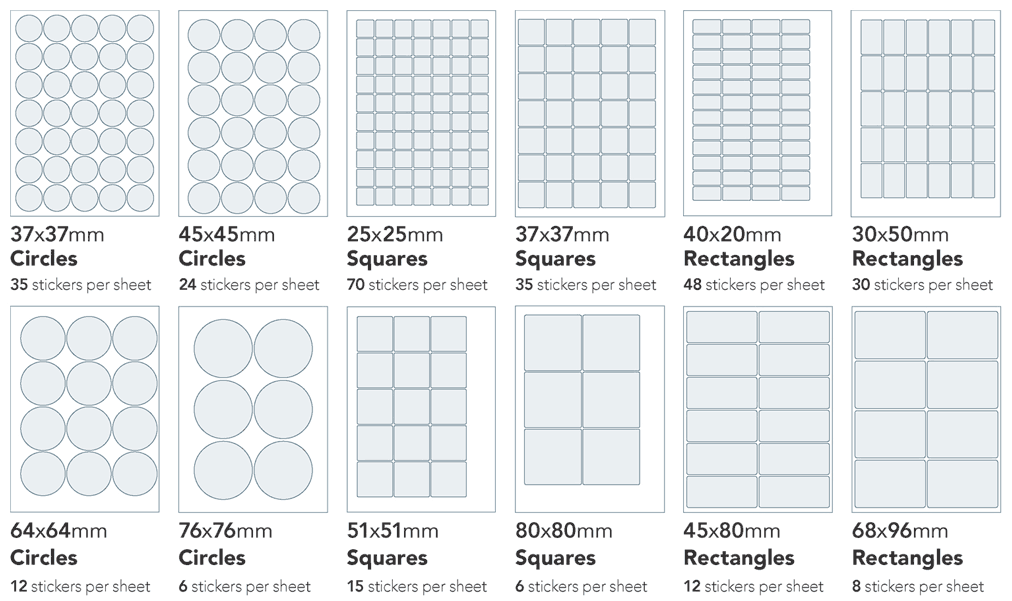

Digital Sticker Sheets

If you are designing any of our precut digital sticker sheets then please ask for a template. If you are supplying us with one copy of the design for us to duplicate then please ask us for the dimensions.

Digital Folders

Our Digital Folders are cut and shaped before they are printed on our digital equipment. That means that you don't need to supply us with a cutter guide.

We have a template available for you to design within, please ask for a copy. The template contains guides on the Finishing Layer to indicate the cut and scored elements of the Folders to help you layout your design.

Thin White Border

There is a 10mm non-printable area around each panel, which results in a thin white border on each panel, illustrated above. The white frames are the non-printable areas, artwork must not enter these areas.

Quiet/Safe Zone

There are quiet zones around the interlocking flaps and and business card slots (shown above), we recommend that artwork stays clear of these zones.

How to supply Scratch Card files

Scratch Card Templates

Download an appropriate InDesign Template to start your design from.

Security

The method used for producing the scratch panels is not a high-security process and thus is not recommended for prizes of high value. The best type of prizes are ones that are low value to you, but high perceived value to the end user.

Scratch Cards are available with a latex panel applied to a shape of your choice. We use the DIE-CUT FORME colour swatch in our templates to indicate the scratch off latex area in your artwork.

Winning & Losing Cards

Each variation may be designed to be a ‘winning’ or ‘losing’ card.

Ordering multiple variations

For Scratch Cards with multiple variations (250 x prize one, 1,000 x prize two), please add one set of the required quantity to the Basket, skip the file upload step, then select the Duplicate icon next to the product title to create additional variations of the same product (you can change the quantity for each item in your Basket before proceeding to checkout).

Indicating the prizes to go under the latex panel

Text or symbols for the game or prizes under the latex panel should be included on the artwork on the same layer as main artwork for the card.

To avoid the end-customer seeing through the latex, we recommend that the artwork under a scratch panel is set to up as follows:

• The background should be 20% black.

• Graphics should use only tints of black, between 30% and 50%.

• Text should only use a black 50% tint.

WARNING: Any deviation from the above specification may produce unexpected results and your artwork may be visible through the latex.

Make sure your artwork under the scratch panel has suitable contrast – i.e. don’t use 8 pt type in 30% black and expect it to be visible!

How to add the latex panel to your artwork

-

The latex panel needs to be supplied as a shape above your artwork filled with the special DIE-CUT FORME spot colour swatch. This swatch must remain as a spot colour and must not be adjusted in any way.

-

Set the DIE-CUT FORME elements to Overprint from within your design application.

-

Bleed the DIE-CUT FORME shape at least 1mm beyond the edge of the game panel that is to be behind the latex panel.

Design with a little tolerance for mis-registration

The latex is applied using a screen printing process, and registration with print can vary by ±2 mm. This means you should expect the panel element to move around the page by up to ±2 mm.

The latex panel should not be bled off the edge of the artwork, scratch panels are recommended to not encroach into the quiet zone.

Keep the panel shape simple

Keep the panel shape simple

Simple shapes are allowed for the scratch panels. These include squares, rectangles, circles and diamonds.

Avoid:

- Acute angles;

- Corners with a small radius.

Avoid bleeding the latex shape over the edge

Avoid bleeding to the edge as chipping and flaking may occur once the job has been guillotined.

Vectors only for the latex panel

Latex must be supplied in vector format.

Multiple panels

You may position any number of scratch panels anywhere on the front of the design with a minimum space of 4mm between each.

Minimum latex panel size

The smallest shape recommended is 10 mm square. Anything smaller is produced at your risk as the process becomes unpredictable.

Scratch Card Reverse

The reverse of a Scratch Card can use CMYK but the maximum recommended level is 225%. For large areas of colour over 20mm square we would advise to keep the ink below 150% if possible.

As the reverse is uncoated and highly absorbent uncoated paper, which can be prone to set-off when large blocks of solids are used.

For the best results we recommend avoiding:

- Solids, i.e. blocks of 100% black, on the reverse;

- Solids over 150% total ink in large areas;

- It's best to avoid bleeding solid colours over 150% total ink over the page edge.

In addition, the heat of the lamination process can cause such areas to become tacky and attach themselves to the glossy front of the sheet beneath it in the pile.

How to supply Digital stickers

Supplying Digital Stickers

Take a look at our general guidelines for Supplying Digital artwork.

These are designed as sheets containing a grid of stickers. The area is yours to use, so you may place a different variation in each shape, or make them all identical.

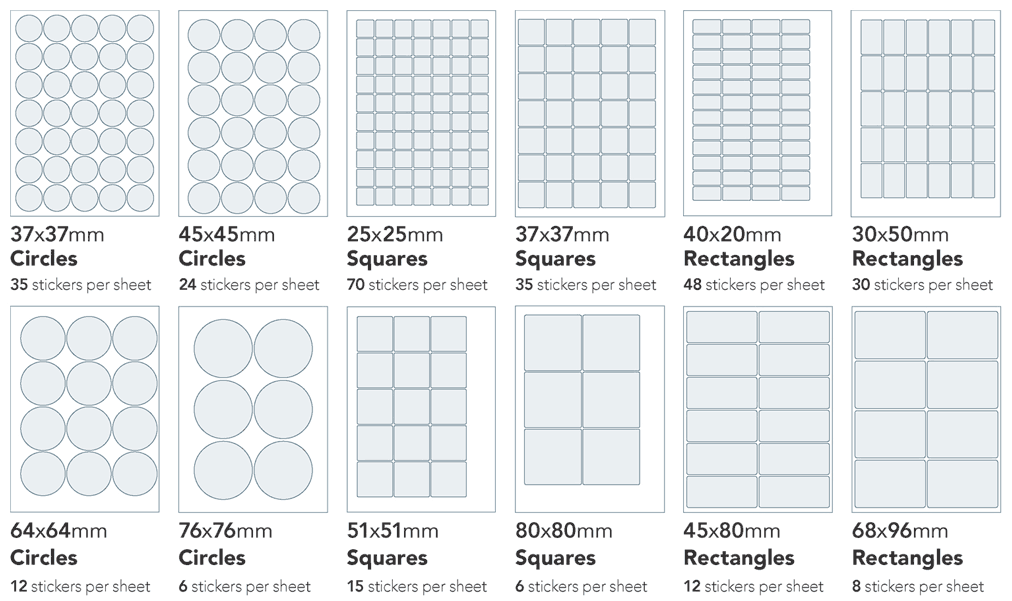

Digital Stickers are delivered as A4 sticker sheets and the number of stickers per sheet depends on your chosen style.

We print the stickers on SRA3 sheets and then cut them in half prior to despatch.

The prices and quantities we display are for sheets of stickers. So if you choose a quantity of 20 for 37 mm Circles, then you will be ordering 700 stickers, as 20 × (A4 sheets having 35 stickers each).

View and compare all the options in the Digital Stickers product group:

| Product code |

Product name |

Printed |

|

FFKSC10

|

Digital Sticker Sheets: Circles 37mm |

35 per A4 sheet |

| FFKC45 |

Digital Sticker Sheets: Circles 45mm |

24 per A4 sheet |

| FFKS2525 |

Digital Sticker Sheets: Squares 25x25mm |

70 per A4 sheet |

|

FFKS3737

|

Digital Sticker Sheets: Squares 37x37mm

|

35 per A4 sheet |

|

FFKR2040

|

Digital Sticker Sheets: Rectangles 20x40mm |

48 per A4 sheet |

|

FFKR3050

|

Digital Sticker Sheets: Rectangles 30x50mm |

30 per A4 sheet |

| FFKC64 |

Digital Sticker Sheets: Circles 64mm |

12 per A4 sheet |

| FFKLC10 |

Digital Sticker Sheets: Circles 76mm |

6 per A4 sheet |

| FFKS5151 |

Digital Sticker Sheets: Squares 51x51mm |

15 per A4 sheet |

| FFKS8080 |

Digital Sticker Sheets: Squares 80x80mm |

6 per A4 sheet |

| FFKSR10 |

Digital Sticker Sheets: Rectangles 45x80mm |

12 per A4 sheet |

| FFKLR10 |

Digital Sticker Sheets: Rectangles 68x96mm |

8 per A4 sheet

|

Rules specific to Digital Stickers:

Examples of poor design:

- Backgrounds that end exactly on the cutting edge: any slight misregistration will cause a white edge to be visible (tolerance for movement is ± 2.0 mm).

- Essential items are too close to the edge: misregistration will cause these items to appear misaligned, or even crop them (tolerance for movement is ± 2.0 mm).

- Designed margins and borders: misregistration will cause these items to appear misaligned (tolerance for movement is ± 2.0 mm).

Examples of good design:

- Text is clear of the Quiet Zone;

- Backgrounds are adequately bled.

How to supply Digital Full Colour NCR

Digital Full Colour NCR's are printed on our digital press. That means they can be printed in full process colour on both sides along with optional sequential numbering and drilling.

Pads are available in sets of 50 in 2 or 3 parts with board backing and white inserted/removable writing shield.

Sets are available in individual sets of 2 or 3 parts.

Paper sequence is only available in:

- 2 part - WHITE/YELLOW

- 3 part - WHITE/YELLOW/PINK

All parts are printed with the same artwork.

Glue edge

You can choose any edge to be glued.

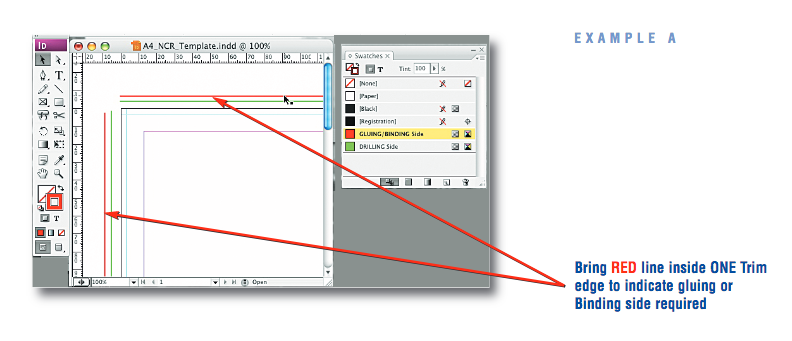

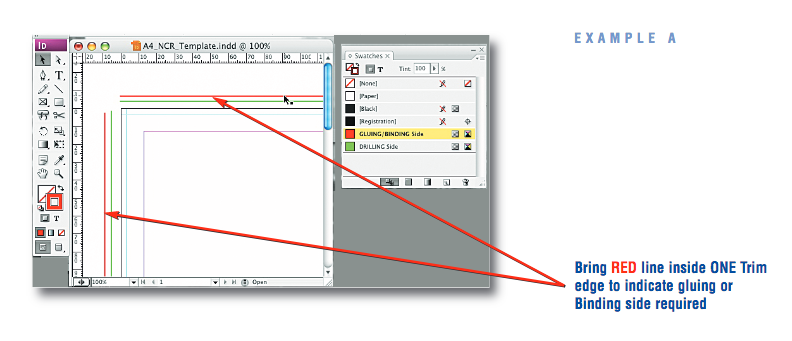

To indicate which edge is to be glued, apply a 0.25 pt red line (process colour: 100M, 100Y) to the desired page edge over the normal black 0.25 pt border. This red line must not be set to overprint.

By default the template will have a red line at the top edge. This must be changed to your desired gluing edge.

Sequential Numbering

The numbering is printed as variable data, which means you can specify any colour in CMYK, and any size in one position only.

The font needs to be Arial.

Starting number must be on the PDF in the exact colour, size and font. This number must be set to overprint. Do not convert the number to outlines.

Drilling

Two drill holes are available in 6mm diameter.

Centre radius may be between 10 mm and 65 mm from an adjacent straight edge.

If you need to have a hole drilled less than 10 mm from a straight edge, you may do so only if the position is 10–65 mm from another adjacent edge.

On the artwork, place a cross + of diameter 2 mm to indicate the drilling position, line thickness 0.5 pt, and of a colour that contrasts with the background.

Leave a clear zone of 5mm around each hole.

Ink coverage

Avoid designing with large areas of solid ink, a large area is defined as an area larger than 50 x 100mm.

If you are just using black, leave as 100% Black.

Tinted areas to be written on with more than 8% tint/shade value of colour may cause carbon transfer problems on duplicate copies. Keep tint/shaded areas between 5-8%.

Maximum recommended total ink level is 225%.

Printing on the reverse

i.e. terms/conditions etc, it is advised to tint/shade content to a maximum of 60% which reduces show-through on the front of document.

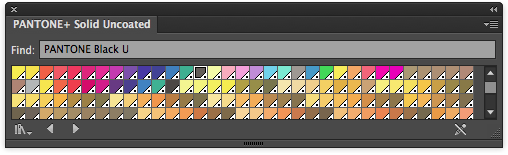

How to supply NCRs ( with 1 or more spot colours)

File Supply Format

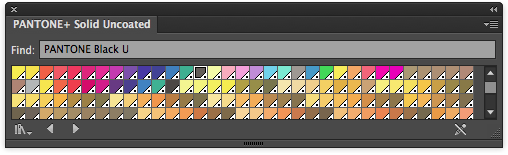

- File Type: PDF only

- Colour Space: Pantone Solid Uncoated or 100% Pantone Black U

- Vector or Bitmap: Either. Supply images at 300dpi

- Transparency & Blends: Make sure ALL transparency have their layers Flattened.

- Fonts: Convert ALL fonts to Outlines/Paths.

Setting up your Page — Bleed & Quiet Zones

Quiet Zone on all edges of Sets, Pads and Books should be 5mm from the trim edge.

If you specify drill holes as additional finishing, be sure to adhere to a quiet zone of 20mm from the trim edge on the side you have specified the drill holes.

NCR Sets only

Leave 5mm from the trim edge clear of any design.

Do not bleed off the glue edge with Sets. You cannot print in this area as ink and the glue we use to group the Sets do not like each other and the process will not work.

NCR Books only

When you have chosen your binding edge, be sure to set up your artwork leaving at least 15mm from the trim edge clear of artwork on the bound edge — anything placed within 15mm will be covered with the binding.

Pantone Colour Library

Pantone + Solid Uncoated

Danger Design Elements — things to avoid

- Thin Lines: 0.5pt minimum

- Avoid large areas of solid ink

Numbering

- Up to 7 digits

- Use Helvetia Condensed Bold 18pt to get a good representation

- Numbering can move by 2.5mm in either direction.

- Positioning: Maximum of 50mm from the top of the page

- One position only

- Colour the start number in Red (100M, 100Y)

- Numbering will be printed in Black Ink only.

- Set number to Overprint

- Convert numbering to Outlines/Paths

Indicating Gluing/Binding Edge

In all the spot colour NCR templates there is a RED overprinted line for you to use to indicate which side of the artwork you want to be glued/bound. Place the red line just inside the page edge as per the example below.

Specifying Optional Drill Holes

To indicate optional drilling (which may also be on the same side that the job is glued or bound), place the overprinted line on the side you want drilled. Let us know when you place your order if you want either a 2-hole Drill or 4-hole Drill.

You do not need to position the drill holes this is done automatically from the information you provide i.e. if you place the green line along the left of the artwork and add finishing for 2 drill holes, it will be drilled on the left edge with 2 holes, positioned for standard 2 hole binding.

How to supply Greeting/Christmas Cards

Christmas Card Templates

Download the appropriate InDesign template to start your design from.

The crease and parallel cuts are present as part of the template, and must not be adjusted. See

Die Cuts for more information.

Lamination & Special Finishes

When supplying your files it's important to supply the first page of your PDF as the front/outside. This is the side we apply our Gloss Lamination to. Matt Lamination is applied to both sides as standard on our 400gsm stocks.

Our Spot UV, Foil and Windowed/Shaped cards are also supplied with the finish on page one of your PDF.

Cover picture overlaps crease

When designing greetings cards with a front panel background that should touch the fold, ensure that the picture overlaps the fold by 1mm.

This allows for production tolerances when creasing, and prevents a contrasting stripe (from the adjacent panel) showing on the front face of the finished card. Remember to manage your customer’s expectations that there may be part of the front design just visible on the back.

Cuts parallel to the crease

Folding products on heavy board (e.g. greetings cards, folding business cards, etc.) now contain die-cut lines to form the two cuts parallel to the centre crease. This should help the edges to meet up correctly when folded. Do not remove these lines.

Landscape Greetings Cards

When viewed flat, the inside artwork needs to read upside-down relative to the front.

Windowed Christmas Cards

Our Windowed Christmas Cards allow for a simple cut-out shape on the front panel.

Please see Die Cuts for more information.

How to supply Etched, Frosted Vinyl Window Panels and Decals

Product Summary

Frosted or etched windows are delightfully elegant. They look like your windows have been sandblasted. Particularly pleasant and understated for period properties. Like decals, choose the areas you want to be cut-out. Supplied pre-cut on backing paper which fixes to the inside of the glass.

File Supply

Shaped, etched and frosted window stickers are easy to set up, you basically just supply a mask of the area to be frosted. Here are some extra details

Colour use

Any areas that require frosted vinyl should have a 100% Magenta fill and any areas that are to be discarded should be blank or white. Do not include any other colours in your artwork.

File Type

You need to supply .EPS files, these can be produced from all the major graphics packages.

Fonts

Please convert all fonts to outlines.

Design detail

It is important that all edges are defined within the artwork and that any strokes and fonts have been outlined. Do not place duplicate lines, text or shapes that sit on top of each other.

Imposition

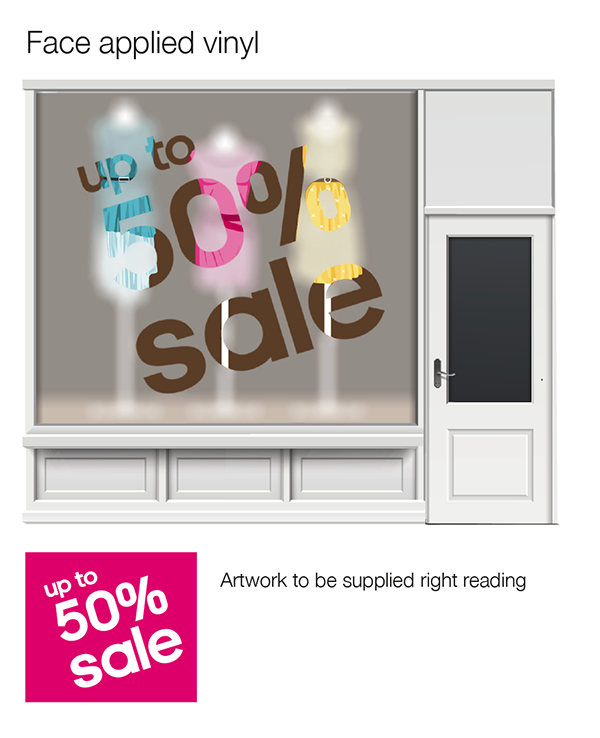

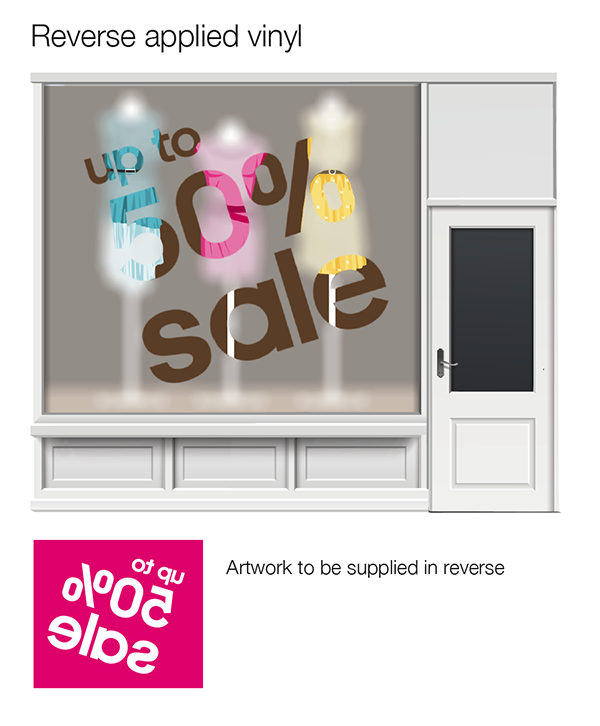

Designs can sometimes be abstract and there is an option to face or reverse apply the vinyl. Your finishing notes within your job will indicate this and your EPS file should match.

Etch on face: Etching on the face means the back of the graphic sticks to the glass and artwork is supplied right reading.

Etch on reverse: Etching on the reverse means the front of the graphic sticks to the glass and artwork is supplied in reverse

How to supply Letter and Logo Window Decals

Product Summary

The term Window Decals refers to partial covering of a window with shaped graphics or individual cut-out lettering, like a telephone number, logo or icon.

Our printing presses are equipped with laser controlled cutting equipment, allowing us to combine window coverage with highly individual decal work. We use monomeric vinyls which are made for flat surfaces, short, medium or long term applications. Outdoor durability from 2 to 4 years.

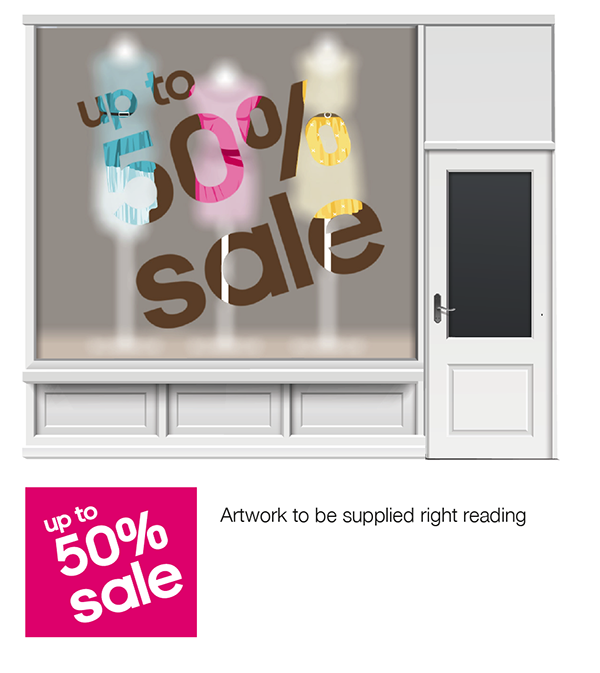

Imposition

Reverse applied: Please supply your artwork right reading. Production will reverse your artwork for this product.

Special Requirements

1) Node/Anchor Point Limits

| Product |

Max Node Complexity per file |

| Cut-out Figures |

40 |

| Shaped/Drilled Boards |

40 |

| Shaped Vinyls (Decals) |

40 |

| Selfie Frames |

10

|

| Cut-out Lettering |

30 characters |

2) Solid shape cut paths

Ensure any die cut paths are solid shapes including at the trim edge where there are straight edges. A solid shape is a "compound path", this means that it's a closed shape with no open ends. This includes straight edges as there is no guillotining on these products.

3) Cutter guide set up

Your shape needs to be set in a 2pt stroke line using the DIE-CUT FORME swatch that is available within the template. Your line also needs to be set to overprint. Note point 3 above about the shape having to be a complete shape, including any straight edges.

How to supply files that require White Ink

Getting the most from White_Ink

Designs with clear unprinted areas

If you are printing partial coverage, with clear unprinted areas then you will usually need to add a White_ink layer to print behind any printed areas.

If you do not add this, the printed areas will appear lighter and slightly transparent a bit like a stained glass window.

How to supply your White Ink elements

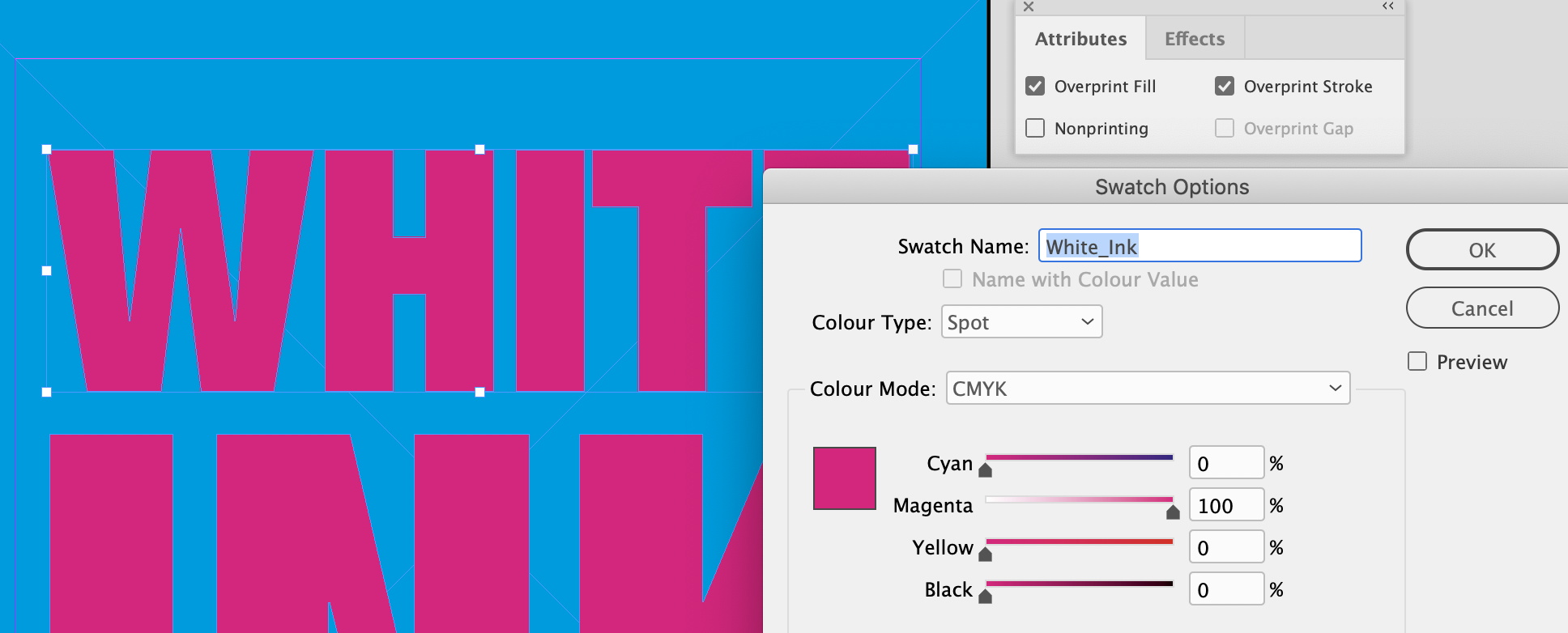

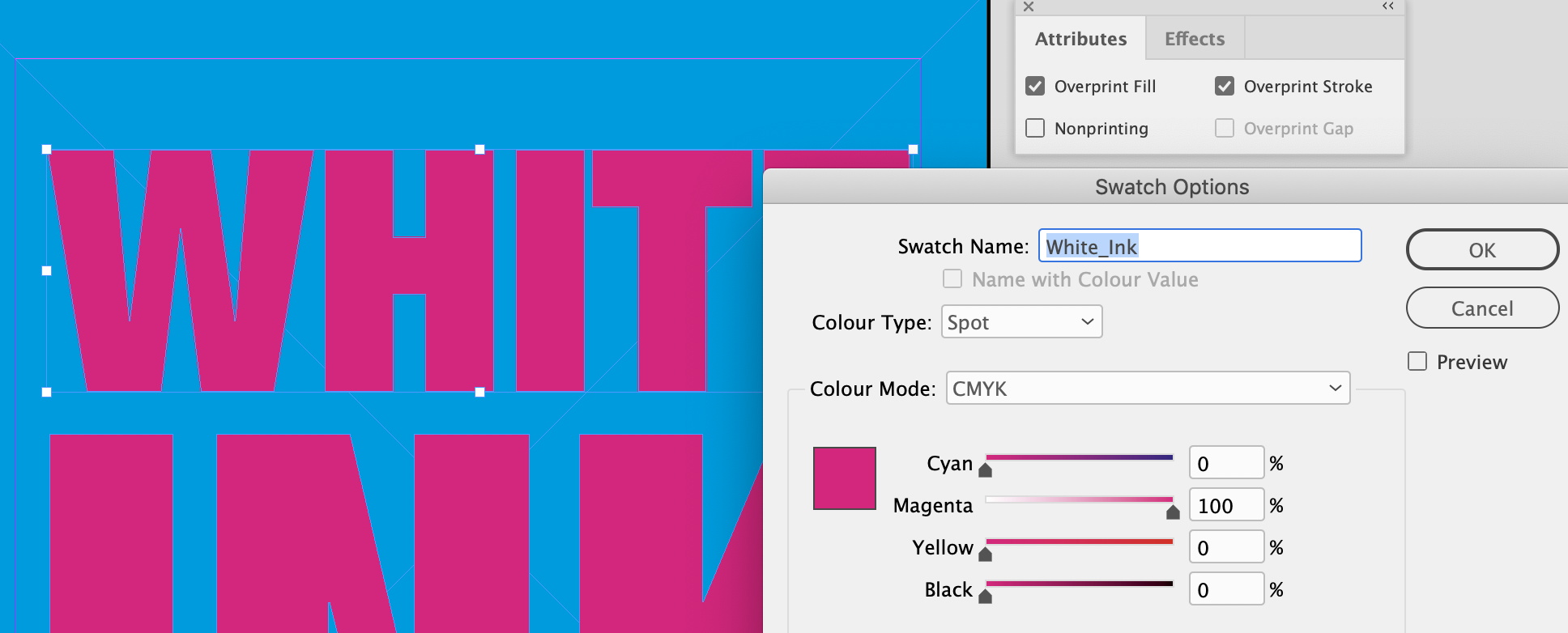

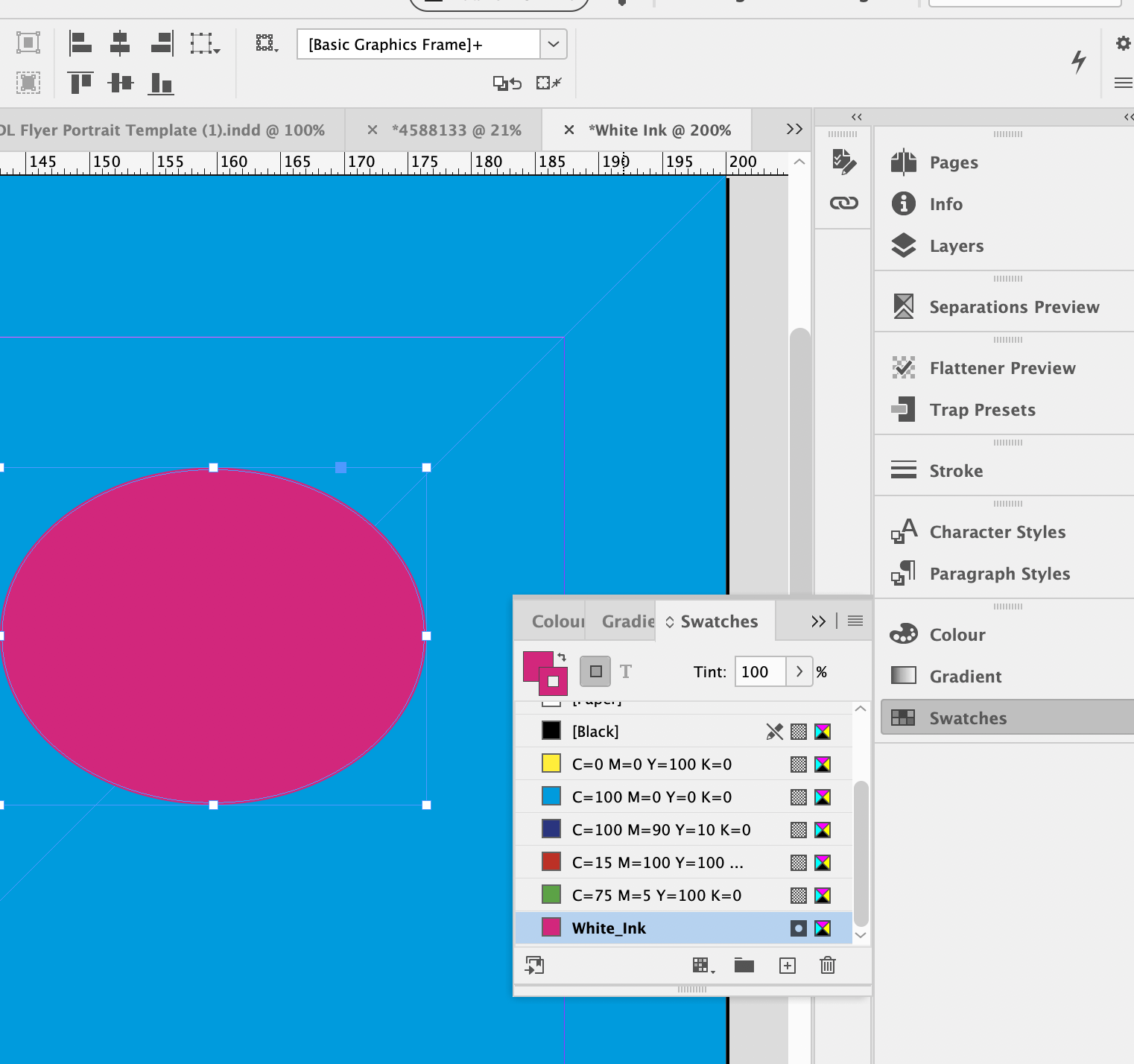

All of our InDesign templates include specific colour swatches for all finishing options or use the instructions below to set up the 'White_Ink' spot colour yourself:

- Create a New Colour Swatch in InDesign.

- Name the swatch White_Ink

- Set Colour Type to Spot

- Set Colour Mode to CMYK

- Colour Make-up is 0% Cyan, 100% Magenta and 0% Yellow

- Set swatch to Overprint ()

.png)

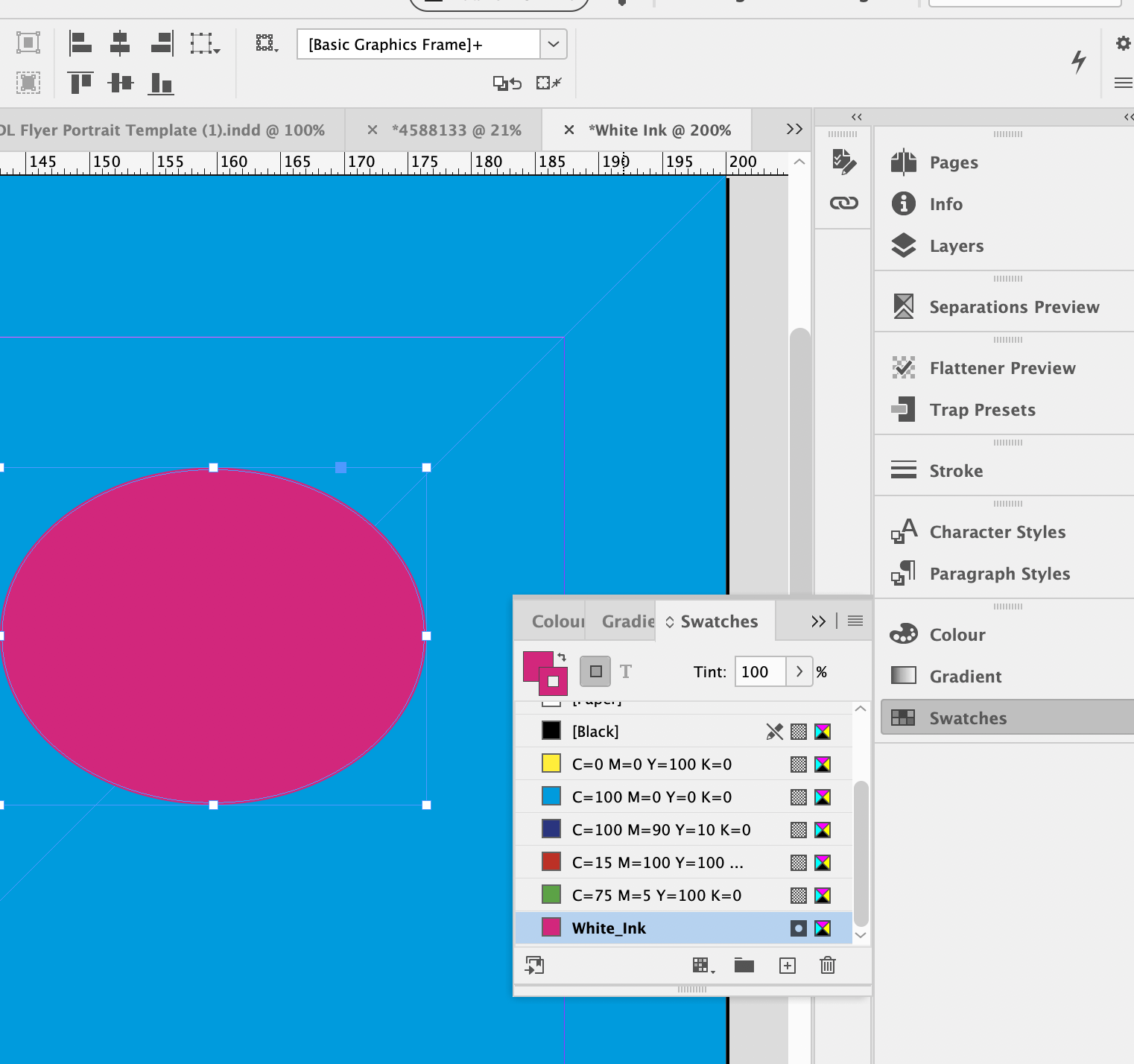

How to add the White Ink to your artwork

-

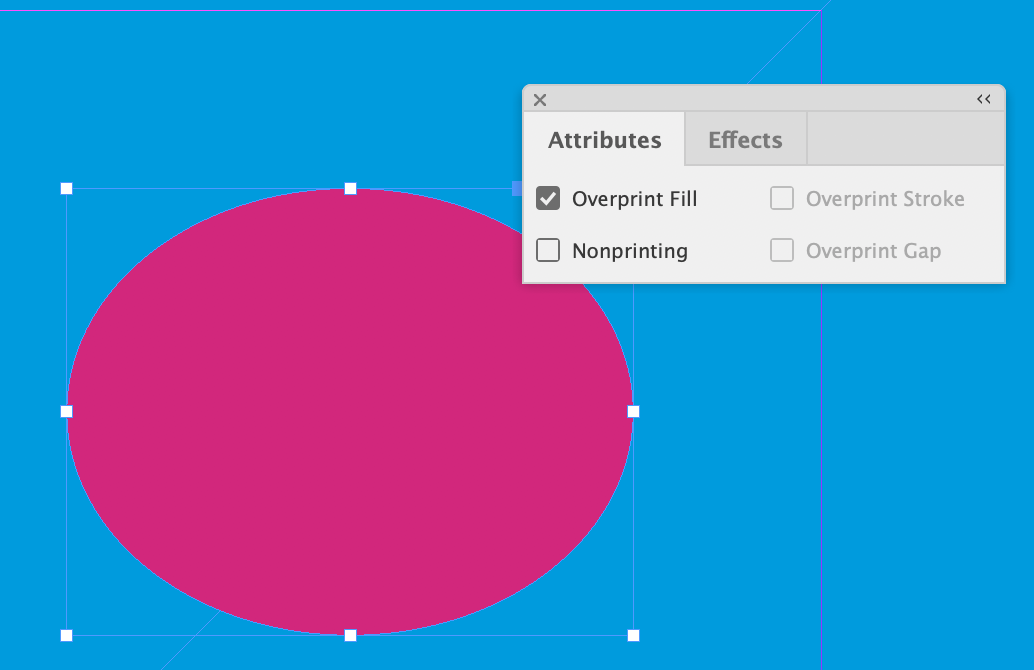

Place White_Ink elements above your artwork (e.g. on the Finishing Layer or brought to front on the top-most Artwork Layer) using the special White_Ink spot colour swatch. This swatch must remain as a spot colour and must not be adjusted in any way.

-

Set the White_Ink elements to Overprint from within your design application.

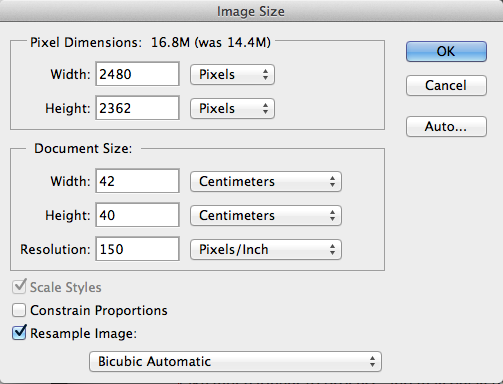

How to supply files for Large Format products

If your product is square cut follow the guidelines below. If you are ordering a shaped large format product, please refer to How to supply files for Shaped Large Format products.

Designing Large Format Posters is slightly different to designing for litho print, partly because of their increased size but also because of the difference in technology.

Increased quiet zone

Ideally you should position images and text at least 10mm from the edge of the Poster. For best results, make your background bleed fully to the edge of your artwork if it is within 10mm of the edge.

Resolution

Large Format Posters are designed to be viewed at a distance (usually of at least 1m). This means that images don’t need to be as high  resolution as on litho printed items. We recommend that the images inside your PDF for Large Format Posters are set at a maximum of 150dpi. Any higher won’t make any difference to final print, but will take much longer to process, and may delay the processing of your job.

resolution as on litho printed items. We recommend that the images inside your PDF for Large Format Posters are set at a maximum of 150dpi. Any higher won’t make any difference to final print, but will take much longer to process, and may delay the processing of your job.

Use of colour

To create a good solid black, use rich black (100% K with 40% C). Don’t use four-colour black and try to keep all elements under 225% total ink limit. It’s best to avoid solid colours of only one ink (i.e. pure cyan, magenta, yellow or black) as these can be susceptible to slight “banding”. Also, any greyscale images should be converted to CMYK prior to being printed on our large format equipment.

Colour variance

Due to the different technology used to produce our Large Format range, and the limitations of the substrates, it’s unlikely that colours will match our range of litho printed products.

Text elements